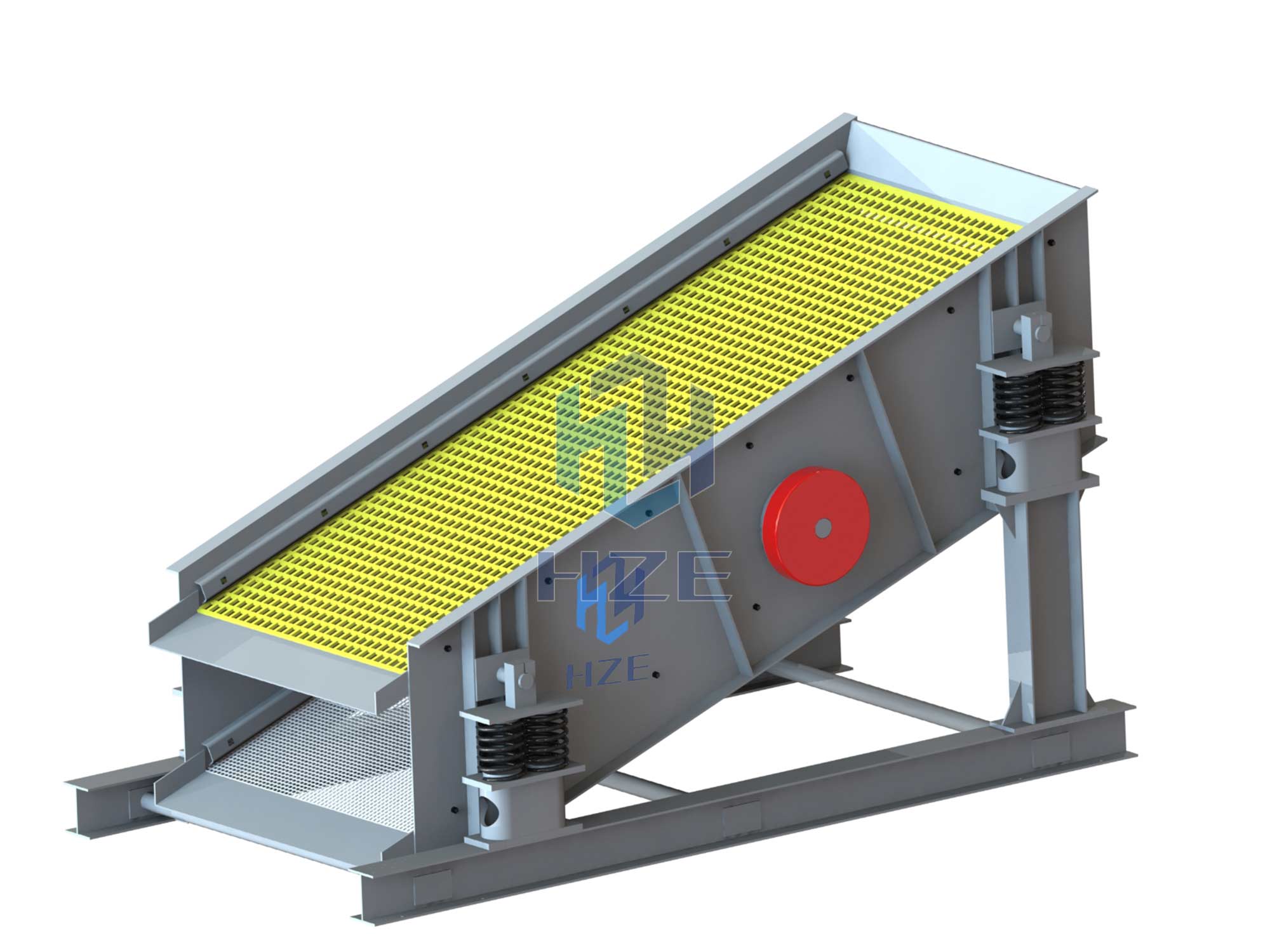

Circular Vibrating Screen

Working Principle

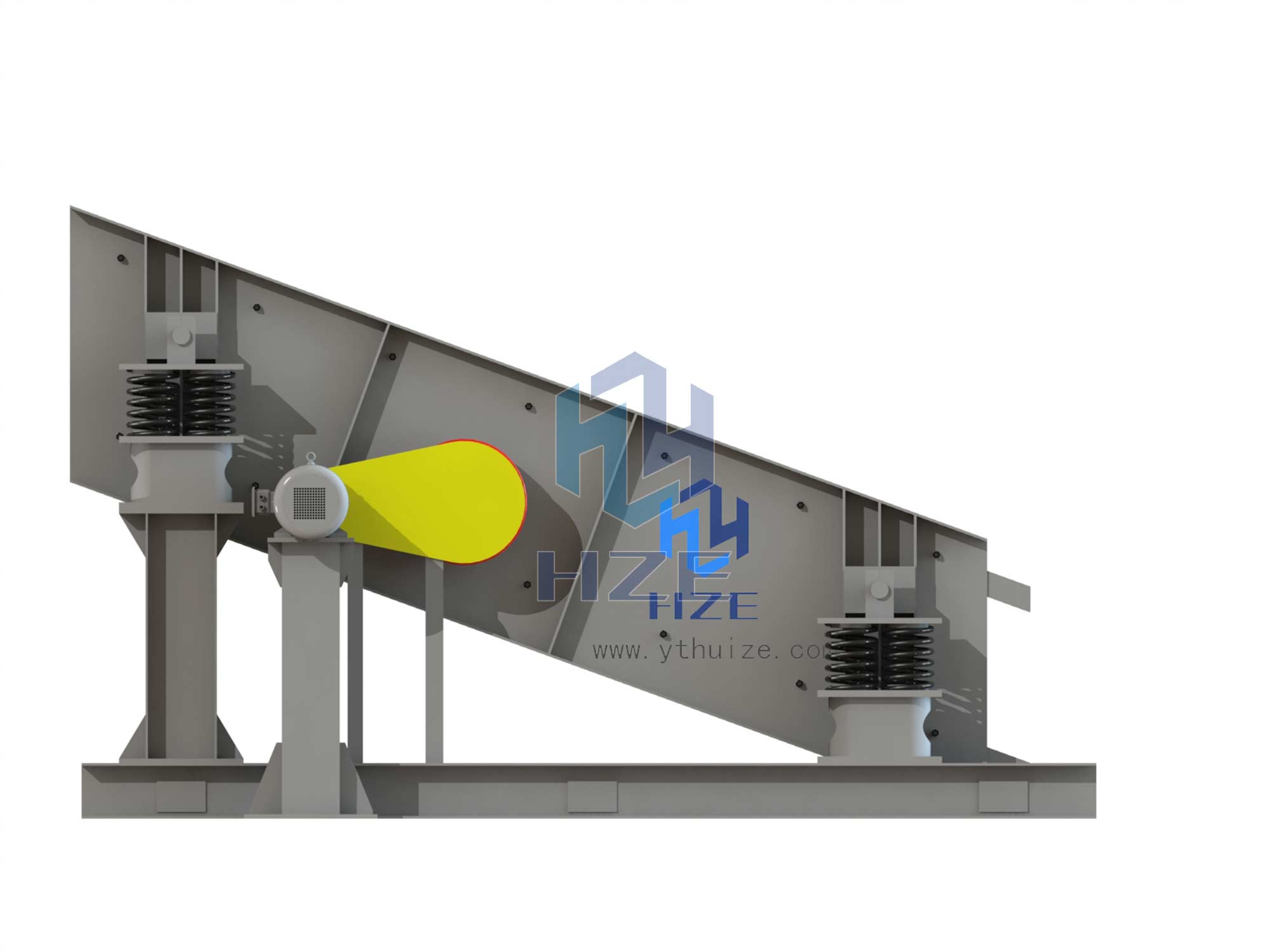

The circular vibrating screen is mainly composed of screen box, screen mesh, vibrator, damping spring, etc. Mounted on the side plate of the screen box and driven to rotate by the motor through V belt, the vibrator generating centrifugal force causes the vibration of the screen box. The vibrator, namely the screen box, vibrates in a circular-like path. During the period, materials with their particle size smaller than the sieve aperture will fall down to the lower deck and become undersize materials; while materials with their particle size larger than the sieve aperture will be discharged from the outlet through continuous jumping, and hence finishing the screening process.

Features

Vibrator with eccentric shaft and eccentric block enables stable operation and highly efficient screening.

The motion trail of this kind of vibrating screen is similar to a circle, and therefore, it is named a circular vibrating screen. It's a kind of high efficiency new vibrating screen with multilayers.

Step out materials stuck in the mesh to prevent sieve blocking.

Low-stress damping spring enables low noise during operation.

Super heavy big clearance bearing enables low operating temperature and long service life.

The frame structure of ring-grooved rivet and plate-type screen box enables high structural strength of screen frame.

Screen mesh can freely choose polyurethane, stainless steel, rubber and other wear-resistant materials.

Application Scope

Circular vibrating screen is one of the most commonly used mining equipment, which is widely used in mineral processing, construction materials, silicate and chemical industries. In the production of small scale, medium scale or large scale mineral processing Plants, it is generally used as the sorting or classifying machine for metal ores of gold, silver, copper, lead, zinc, nickel, manganese, iron, molybdenum, chromium, tin and others, as well as stone, rock, granite, limestone, barite, quartz, graphite, feldspar, fluorspar, fluorspar, etc.

It is also applicable for the dewatering, desliming and medium drainage, etc.

Technical Parameters

Small Size

|

Model |

Screen Deck |

Feeding Size (mm) |

Capacity (t/h) |

Electric Motor |

|||

|

Area (m2) |

Angle (°) |

Aperture (mm) |

Model |

Power (kW) |

|||

|

YA1236 |

4.3 |

20

|

6~50 |

≤200 |

75~245 |

Y160M-4 |

11 |

|

YA1530 |

4.5 |

80~240 |

Y160M-4 |

11 |

|||

|

YA1536 |

5.4 |

95~310 |

Y160M-4 |

11 |

|||

|

YA1536 |

≤400 |

100~350 |

Y160L-4 |

11 |

|||

|

YA1542 |

6.3 |

6~50 |

≤200 |

110~385 |

Y160M-4 |

11 |

|

|

YA1548 |

7.2 |

6~50 |

120~420 |

Y160L-4 |

15 |

||

|

YAH1548 |

30~150 |

≤400 |

200~780 |

Y160L-4 |

15 |

||

Midium Size

|

Model |

Screen Deck |

Feeding Size (mm) |

Capacity (t/h) |

Electric Motor |

|||

|

Area (m2) |

Angle (°) |

Aperture (mm) |

Model |

Power (kW) |

|||

|

YA1836 |

6.5 |

20 |

30~150 |

≤200 |

115~370 |

Y160M-4 |

11 |

|

YAH1836 |

6.5 |

30~150 |

≤400 |

220~800 |

Y160M-4 |

11 |

|

|

YA1842 |

7.6 |

6~50 |

≤200 |

135~430 |

Y160L-4 |

15 |

|

|

2YA1842 |

7.6 |

6~150 |

135~430 |

Y160L-4 |

15 |

||

|

YAH1842 |

7.6 |

30~150 |

≤400 |

340~900 |

Y160L-4 |

15 |

|

|

YA1848 |

8.6 |

6~50 |

≤200 |

150~490 |

Y160L-4 |

15 |

|

|

2YA1848 |

8.6 |

150~490 |

Y160L-4 |

15 |

|||

|

YA2148 |

10 |

6~50 |

≤200 |

175~570 |

Y180M-4 |

18.5 |

|

|

2YA2148 |

10 |

6~50 |

≤200 |

175~570 |

Y180L-4 |

22 |

|

Big Size

|

Model |

Screen Deck |

Feeding Size (mm) |

Capacity (t/h) |

Electric Motor |

|||

|

Area (m2) |

Angle (°) |

Aperture (mm) |

Model |

Power (kW) |

|||

|

YA2160 |

12.6 |

20 |

6~80 |

≤200 |

230~800 |

Y180M-4 |

18.5 |

|

2YA2160 |

12.6 |

6~50 |

≤200 |

220~715 |

Y180L-4 |

22 |

|

|

YA2448 |

11.5 |

20 |

6~50 |

≤200 |

200~650 |

Y180 M -4 |

18.5 |

|

YA2460 |

14.4 |

6~50 |

≤200 |

260~780 |

Y200L-4 |

30 |

|

|

2YA2460 |

14.4 |

6~50 |

≤200 |

260~780 |

Y200L-4 |

30 |

|

DOWNLOAD

DOWNLOAD