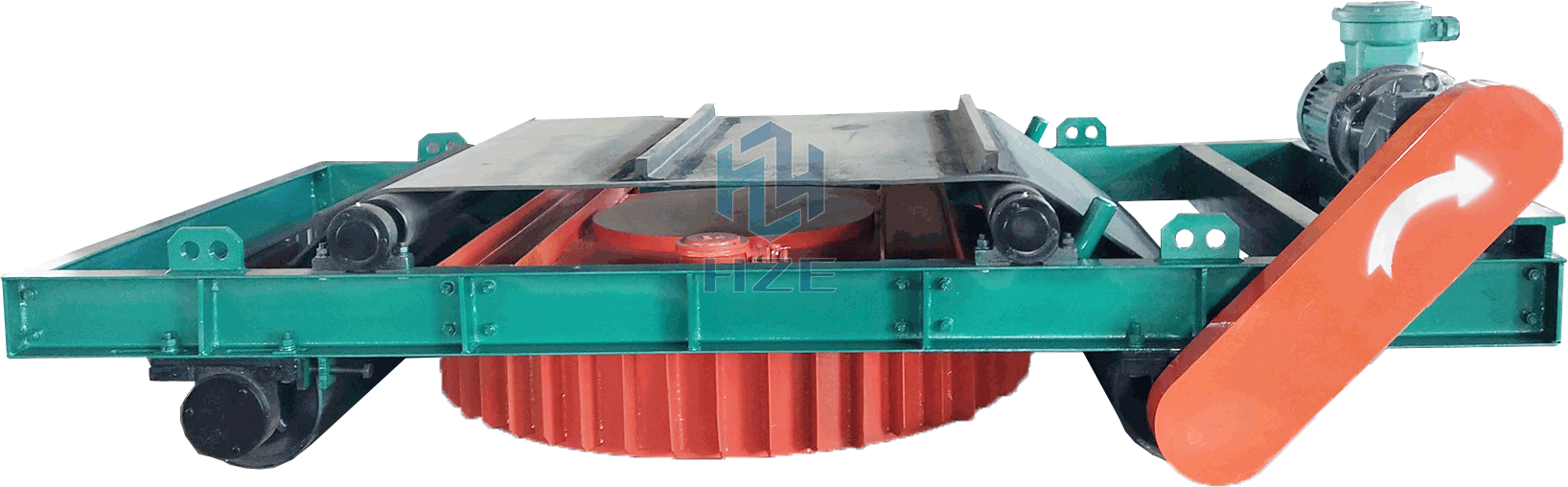

Self-Cleaning Suspended Electromagnet

Working Principle

Deep penetrating electromagnets, incorporating all of the latest innovations in coil design, allow the suspended electromagnet to remove both large and small tramp metal from deep burdens on fast-moving conveyors. The electromagnet is designed for continuous operation at peak performance.

Self-cleaning electromagnet can be mounted in line with the material flow or transverse to remove the ferrous materials over the side of the conveyor.

Features

Optimum design of magnetic circuit brings out large permeability depth and strong magnetic force.

Internal chamber is casted in electrician-specific resin which has the advantages of self-cooled with fully sealed structure and resistance of dust, rain and corrosion.

Wave-fin heat sinks greatly increase the area of heat dissipation to effectively control the temperature.

It can effectively removes 0.1-50 kg ferromagnetic part which is mixed in non-magnetic materials.

Self-cleaning.

Technical Parameters

Small and Medium Size

|

Model |

Belt Width (mm) |

Suspension Height (mm) |

B (mT) |

Material Thickness (mm) |

Power (kW) |

Belt Speed (m/s) |

|

RCDD-5 |

500 |

150 |

60 |

100 |

1+1.5 |

4.5 |

|

RCDD-6 |

600 |

175 |

60 |

130 |

1.6+1.5 |

|

|

RCDD-6.5 |

650 |

200 |

70 |

150 |

2+2.2 |

|

|

RCDD-8 |

800 |

250 |

70 |

200 |

3.6+2.2 |

|

|

RCDD-10 |

1000 |

300 |

70 |

250 |

5+3 |

Big Size

|

Model |

Belt Width (mm) |

Suspension Height (mm) |

B (mT) |

Material Thickness (mm) |

Power (kW) |

Belt Speed (m/s) |

|

RCDD-12 |

1200 |

350 |

70 |

300 |

6.8+4 |

4.5 |

|

RCDD-14 |

1400 |

400 |

70 |

350 |

9+4 |

|

|

RCDD-16 |

1600 |

450 |

70 |

400 |

13+5.5 |

|

|

RCDD-18 |

1800 |

500 |

70 |

450 |

18+7.5 |

DOWNLOAD

DOWNLOAD