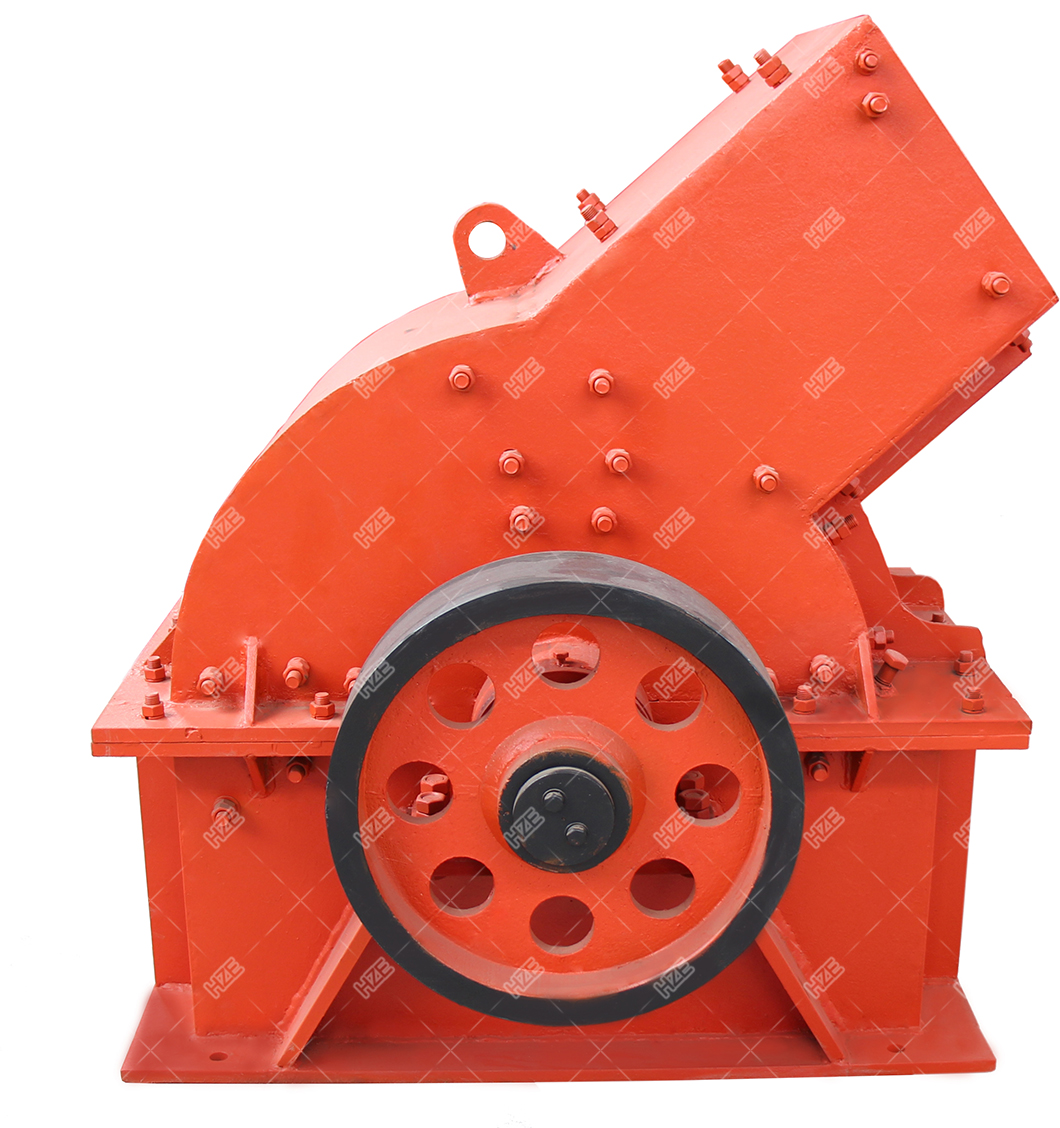

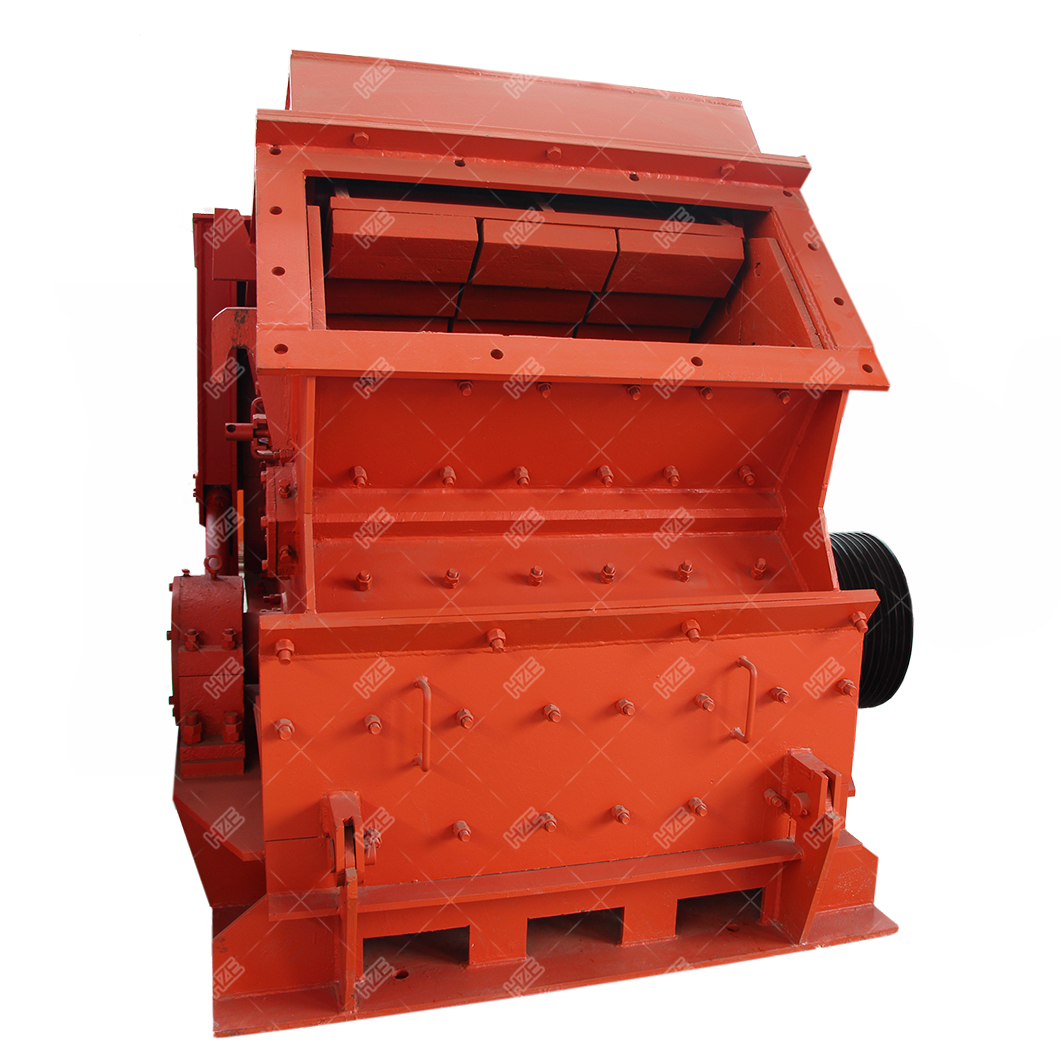

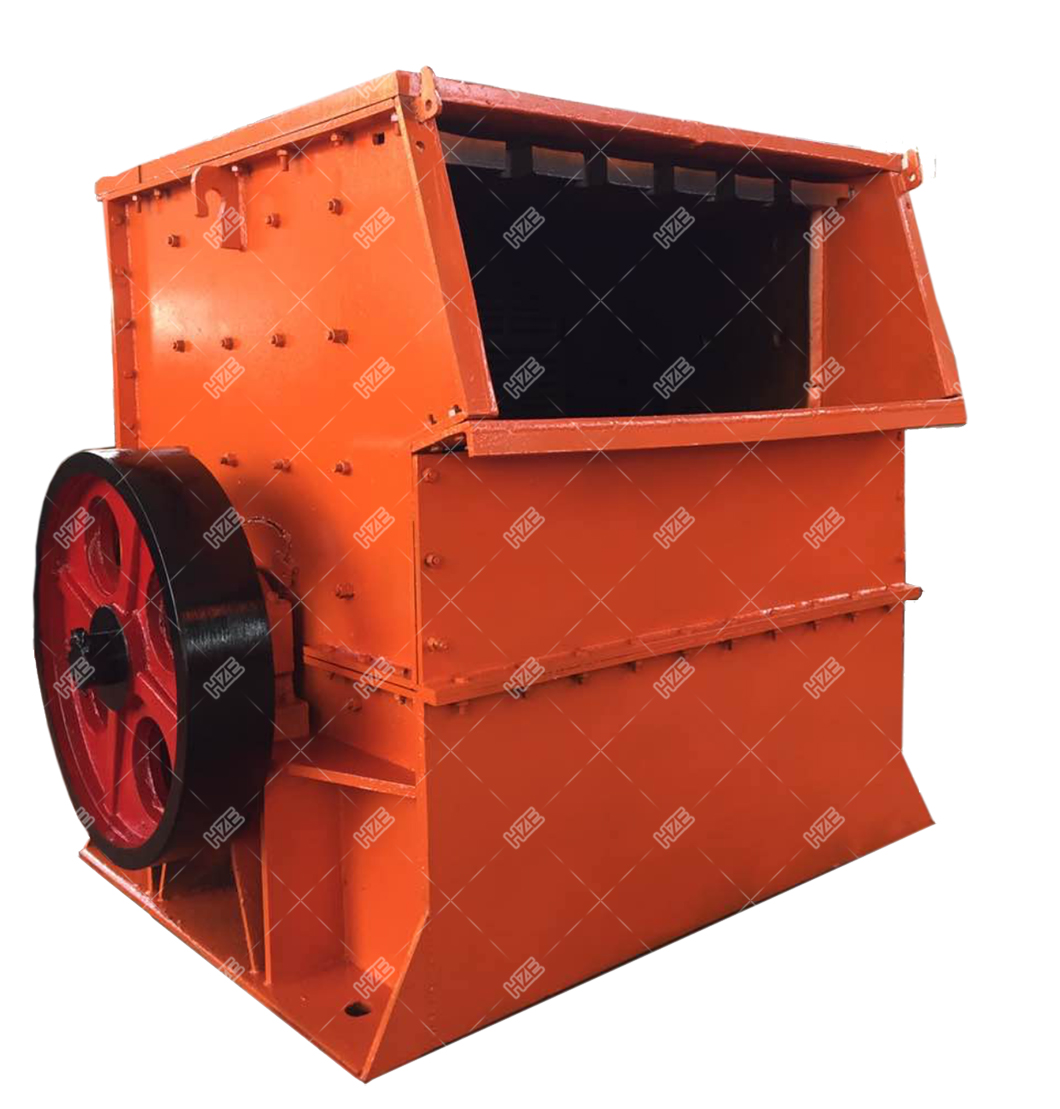

Hammer Crusher

Working Principle

Druing running, the rotor driven by the electric motor or diesel engine rotates under high speed. The materials are fed in the crushing chamber, the rotating hammers fixed around the rotor impact, shear and tear the materials. The crushed materials fall down to the baffle and grizzly bars of the grate by gravity, the oversize materials are hold in the chamber to be re-crushed by the hammers, the undersize materials are discharged of the grate.

Features

The hammers are made of new wear-resistant alloy material and casted by new technology which has good wear resistance and impact resistance.

The mechanical structure of the crusher is simple, it is easy to replace the hammers.

The crushing ratio is big, the product size is small and uniform, the productivity is high.

The product size can be adjusted by variety of the grate gap in order to meet different product demands.

Applications

The hammer crusher is widely used in mineral processing, construction materials, silicate and chemical industries. In the production of mineral processing Plants, it crushes hard or medium hard metal ores of gold, silver, copper, lead, zinc, nickel, manganese, iron, molybdenum , chromium, tin and others, as well as stone, rock, granite, limestone, barite, quartz, graphite, feldspar, fluorspar, etc.

Technical Parameters

|

Model |

Max. Feed Size (mm) |

Discharge Size (mm) |

Capacity (t/h) |

Motor Power (kW) |

|

PC-375×300 |

100 |

<3~15 |

3-5 |

5.5 |

|

PC-600×400 |

100 |

<10~35 |

12-15 |

18.5 |

|

PC-600×600 |

150 |

<10~35 |

18-24 |

30 |

|

PCA-600×400 |

150 |

<10~40 |

20-40 |

18.5 |

|

PCA-600×600 |

150 |

<10~40 |

25-50 |

30 |

|

PCA-800×800 |

300 |

<10~60 |

30-60 |

37 |

|

PCA-1000×1000 |

300 |

<10~60 |

30-80 |

55 |

|

PCA-1200×1500 |

300 |

<10~80 |

60-80 |

110 |

|

PCA-1200×1800 |

300 |

<10~100 |

80-120 |

132 |

|

PCA-1800×2600 |

370 |

<15~120 |

130-500 |

220×2 |

|

PCA-1800×2800 |

370 |

<15~120 |

130-500 |

500 |