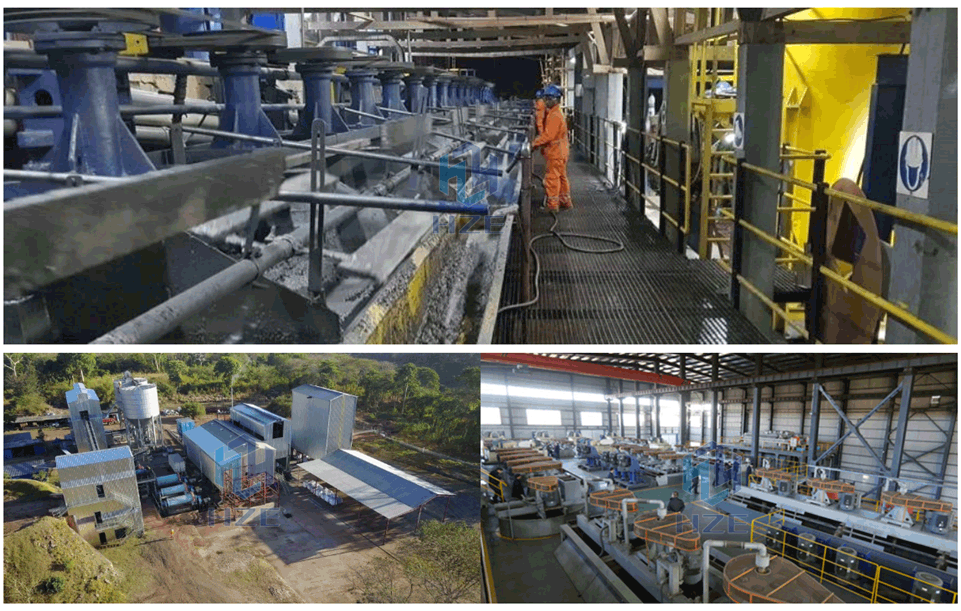

Graphite Beneficiation and Processing Plant

HZE will conduct feasibility studies based on the condition of the raw ore, the metallurgical test report, the customer's mineral reserves and investment scale, and the conditions for building the plant, then propose a complete set of solutions for the plant which includes engineering design, equipment manufacturing and supply, logistics, installation, commissioning, training, trial production and so on to ensure advanced technology, perfect processing, efficient plant construction, reduced investment, environmental protection and maximum benefits.

Graphite is a kind of non-metallic minerals with many excellent properties. High temperature resistance and chemical stability make it an important raw material for refractories. In addition, it has important applications in chemical industry, machinery, electronics, atomic energy and other fields.

According to the crystalline morphology, graphite can be divided into flake graphite (crystalline graphite) and amorphous graphite (cryptocrystalline graphite, earthy graphite). Flotation is the main method of graphite processing, but the flotation of flake graphite is different from that of amorphous graphite. During the beneficiation of flake graphite, great attention should be paid to the protection of large flake graphite.

Flotation process designs vary in complexity depending on degree of liberation and the desired purity of the product. The processes for graphite include: [1] preparation (crushing and coarse grinding); [2] flotation (several rougher, scavenger, liberation and cleaner steps with intermediate regrinding steps); [3] concentrate treatment (dehydration, drying, classification and packaging).

The carbon content of graphite concentrate is generally 85%-93%. In order to obtain high purity graphite, purification process is needed. The purification methods include chemical purification, thermal purification and mixing.