Zinc and Lead Beneficiation and Processing Plant

HZE has extensive experience to recover zinc, lead and other valuable metals by flotation and other processing to provide comprehensive services to large, medium and small-scale zinc and lead mineral processing plants.

HZE will conduct feasibility studies based on the condition of the raw ore, the metallurgical test report, the customer's mineral reserves and investment scale, and the conditions for building the plant, then propose a complete set of solutions for the plant which includes engineering design, equipment manufacturing and supply, logistics, installation, commissioning, training, trial production and so on to ensure advanced technology, perfect processing, efficient plant construction, reduced investment, environmental protection and maximum benefits.

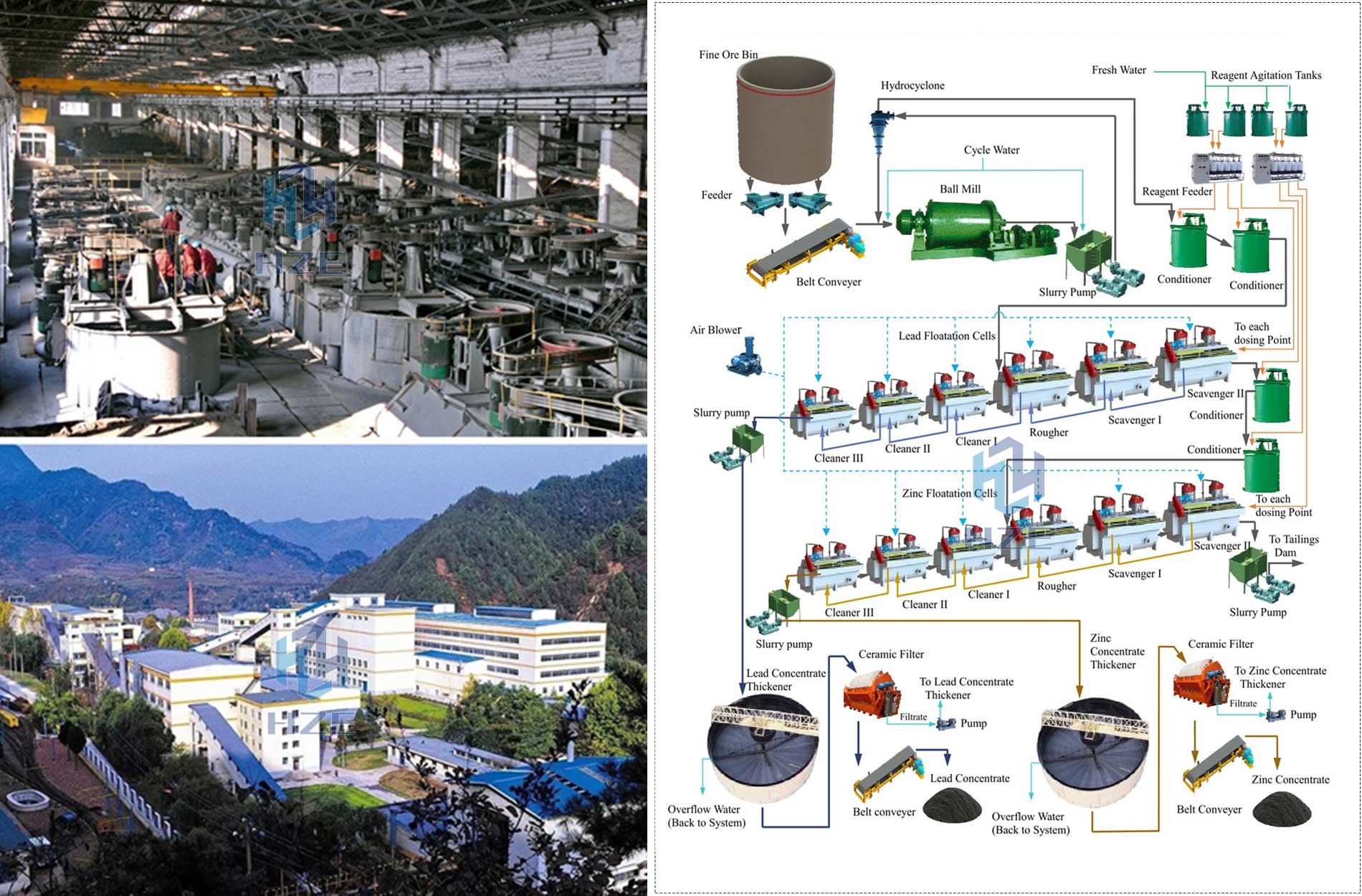

The zinc and lead sulfide ores are sent to the mineral processing plant will be crushed, screened, and ground, then the slurry enters the flotation stage generally. Flotation acts to primary ore sulfides normally, and it is necessary to use appropriate chemicals for slurry mixing and minerals recovery by flotation. Generally the flotation circuit includes rougher, scavenger and cleaner to obtain a satisfactory concentrate.

The flotation sequence of zinc and lead is that lead is recovered preferentially then zinc is recovered. Sometime regrinding may be adopted between lead flotation and zinc flotation.

If the raw materials are mainly oxidized ore, generally zinc is recovered by acid leaching and hydrometallurgy. The oxide ore can be vulcanized then lead and zinc are recovered by flotation but it must be proposed by the strict metallurgical test.

The raw ore may contain other valuable minerals such as gold, silver, copper and iron, etc., which need to comprehensively recover mixed concentrates or by-product concentrates according to the specific conditions of the ore in order to obtain greater benefits.

The concentrate after flotation is generally dewatered by thickening and filtration, and then packaged and sold to the smelting plant.

The tailings after flotation are pumped to the tailings impoundment or the tailings are dewatered for dry stacking.

The following flowchart shows the processing example of the zinc and lead flotation plant (crushing stage omitted):

Zinc and Lead Beneficiation and Processing Plant