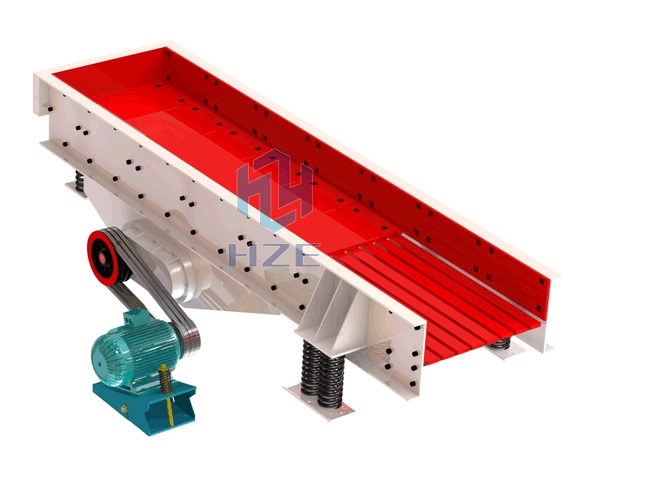

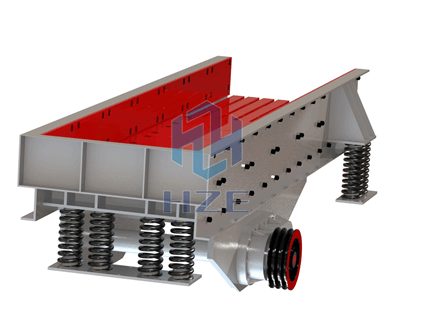

Vibrating Feeder

Working Principle

The vibrating feeder has structural feature of double eccentric shaft vibrators, which can ensure to undertake the impact force generated by the falling big blocks and achieve great feeding ability. The vibrator is made up of double specifically assembled eccentric shafts that mate each other by engage gears. The electric motor drives two eccentric shafts to rotate which will generate great exciting resultant force, and the feeder body will be forced to vibrate on the spring support. The materials are powered by vibration, slide and throw on the feeder trough to make them forward and complete the feeding. When the materials pass through the grizzly, the first half of the feeder, smaller blocks will pass the gap between the bars of the grizzly and fall down., so the smaller blocks can bypass the next crushing and the feeder has screening function.

Features

Stable vibration, reliable operation and long life.

The vibration force can be adjusted.

The excitation source of double eccentric shafts has the features of low noise, less energy consumption, good adjusting performance, and uniform feeding.

The vibration trajectory is straight line, and the front end of the feeding trough is equipped with a grizzly. The processes of feeding and screening are working at the same time, which improves the utilization ratio of the equipment and reduces the cost.

Application

It is widely used as the crushing and screening combination equipment in the fields of metallurgy, coal mining, mineral processing, building materials, chemical industry, abrasive, etc. this equipment is not suitable for feeding sticky or wet materials.

Technical Parameters

|

Model |

Trough L×W (mm) |

Max. Feeding Size (mm) |

Capacity (t/h) |

Eccentric Shaft Speed (r.p.m) |

Power (kW) |

|

ZSW-380×95 |

3800×960 |

500 |

96-160 |

800 |

11 |

|

ZSW-420×110 |

4200×1100 |

500 |

110-180 |

15 |

|

|

ZSW-490×110 |

4900×1100 |

500 |

115-192 |

15 |

|

|

ZSW-590×110 |

5900×1100 |

630 |

350~500 |

22 |

|

|

ZSW-600×130 |

6000×1300 |

750 |

400-560 |

DOWNLOAD

DOWNLOAD