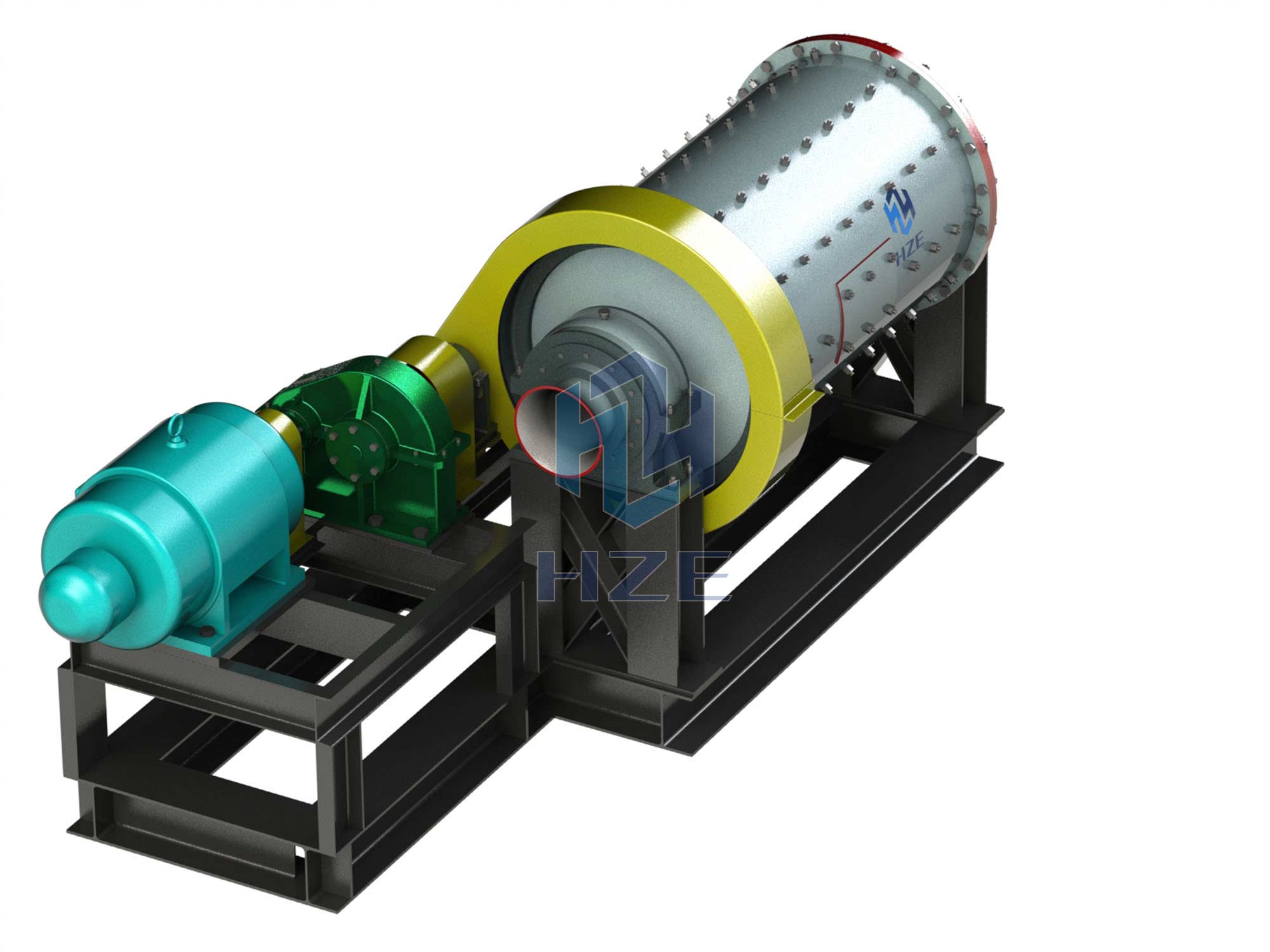

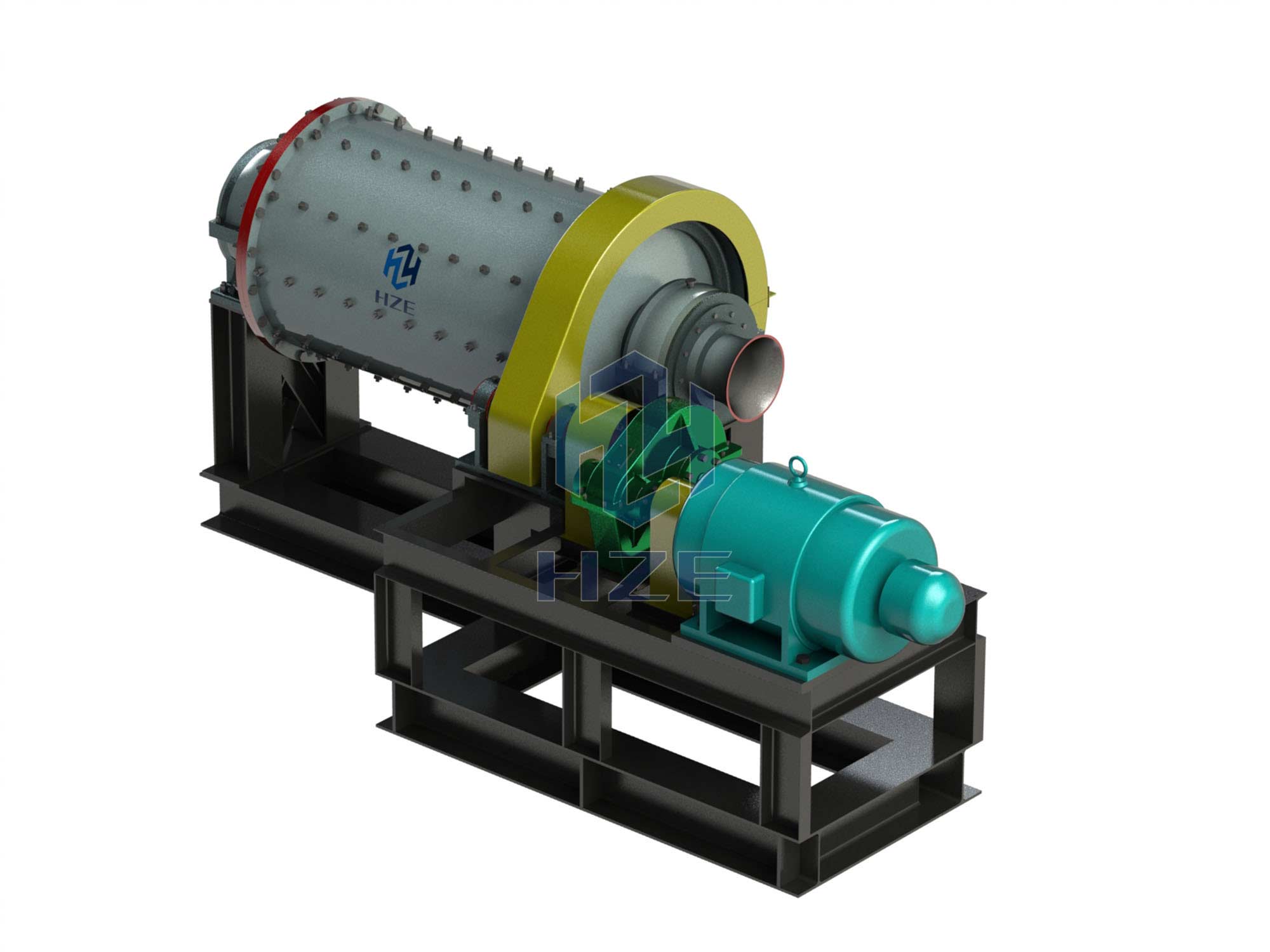

Rod Mill

Working Principle

The transmission device drives the cylinder to rotate. Materials and water are fed from the feeding end of the cylinder. Ores are ground into fine particles by the grinding of steel rods, as well as the impact & grinding of ores themselves. The continuous grinding compels the slurry to move from feeding end to discharging end due to continuous feeding of water and materials. The slurry will overflow by itself when the slurry level is higher than the lower edge of discharging trunnion.

Features

The heads of the mill have big cone angle, this enables the regular movement of the steel rods in mill and avoid distributions of steel rods.

The larger diameter of discharging trunnion is easy for maintenance, and can reduce the slurry liquid and realize rapid discharging.

Even particle size and rarely over-grinding.

Application Scope

Mainly used for rough grinding operation. It’s suitable for the fine crushing and rough grinding in the first grinding stage, especially for processing brittle materials.

Rod mill is one of the most commonly used mining equipment, which is widely used in mineral processing, construction materials, silicate and chemical industries. In the production of small scale, medium scale or large scale mineral processing plants, it is generally used as the grinding machine for metal ores of gold, silver, copper, lead, zinc, nickel, manganese, iron, molybdenum, chromium, tin and others, as well as limestone, barite, quartz, graphite, feldspar, fluorspar, etc.

Technical Parameters

Small Size

|

Model |

Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model |

Power (kW) |

Effective Volume (m3) |

Max. Rod Load (t) |

|

MBY0918 |

900 |

1800 |

Y225M-8 |

22 |

0.9 |

2.4 |

|

MBY0924 |

900 |

2400 |

Y250M-8 |

30 |

1.2 |

3.2 |

|

MBY1224 |

1200 |

2400 |

Y280M-8 |

45 |

2.28 |

6.2 |

|

MBY1530 |

1500 |

3000 |

JR125-8 |

95 |

5 |

13.5 |

Medium Size

|

Model |

Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model |

Power (kW) |

Effective Volume (m3) |

Max. Rod Load (t) |

|

MBYg2130 |

2100 |

3000 |

JR136-8 |

180 |

9 |

24.3 |

|

MBYg2136 |

2100 |

3600 |

JR137-8 |

210 |

10.8 |

29.2 |

|

MBYg2430 |

2400 |

3000 |

JR138-8 |

280 |

11.5 |

31.1 |

|

MBYg2732 |

2700 |

3200 |

JR157-8 |

320 |

15.7 |

42.4 |

|

MBYg2736 |

2700 |

3600 |

JR1512-8 |

380 |

17.7 |

47.8 |

|

MBYg2740 |

2700 |

4000 |

TDMK400-32 |

400 |

20.4 |

55.1 |

Big Size

|

Model |

Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model |

Power (kW) |

Effective Volume (m3) |

Max. Rod Load (t) |

|

MBY3040 |

3000 |

4000 |

JR157-8 |

440 |

26 |

70.2 |

|

MBY3245 |

3200 |

4500 |

TDMK800-36 |

800 |

31 |

83.7 |

|

MBY3645 |

3600 |

4500 |

TDMK1250-40 |

1250 |

41.8 |

112.9 |

|

MBY3654 |

3600 |

5400 |

TDMK-1600 |

1600 |

49.7 |

134.2 |

DOWNLOAD

DOWNLOAD