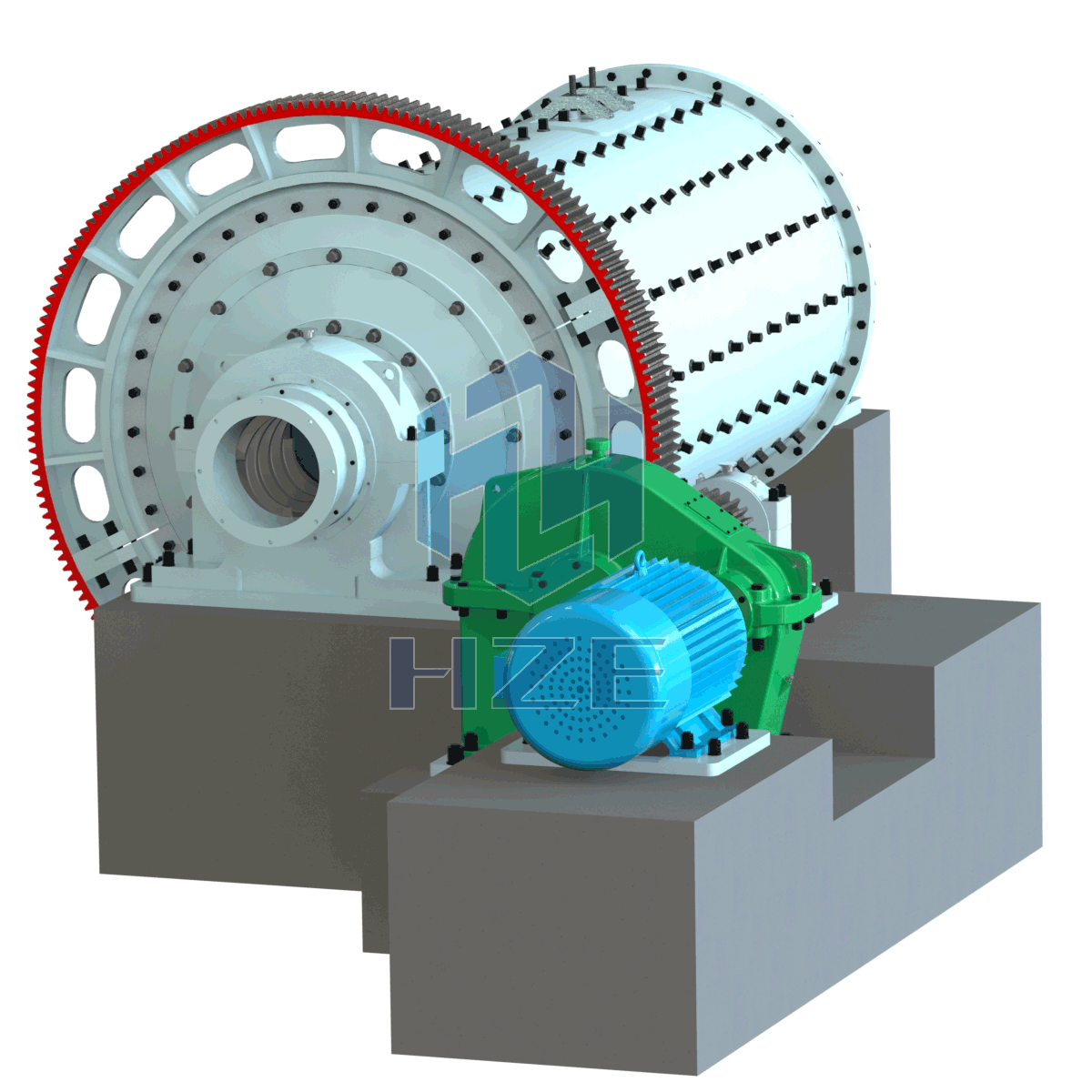

Overflow Ball Mill

Working Principle

The transmission device drives cylinder to rotate. Materials and water are fed from the feeding end of cylinder and materials are grinded by impact and grinding of steel balls and ores into fine particles. The continuous grinding compels the slurry to move from feeding end to discharging end. The grinded particles with proper size and water mix to slurry which flows out of the discharge end of the ball mill. Features

Features

Large double row self-aligning rolling bearings or hybrid bearings are used to reduce the friction force which is easy for starting and the energy is saved by 20-30%.

Grooved ring high manganese steel liners are used to increase the contact surface of ball and ore, strength the grinding, lift the ores, and reduce the energy consumption.

The steel frame can be used for the ball mills with diameter 2.7 meter or less in order to design and manufacture the modular plant, reduce the amount of civil construction and install the machine easily.

Large discharging outlet is designed for more capacity.

Depending on the customer's site conditions and demands, the electric motor is selected high-voltage or low-voltage type, and the liners materials can be high manganese steel or wear-resistant rubber. The brand of the motor or reducer can be chosen by the customer freely.

It is recommended that the ball mills equipped the hybrid bearings should have the hydraulic jacks to lift the cylinder easily for installation and service.

The ball mill runs smoothly and reliably.

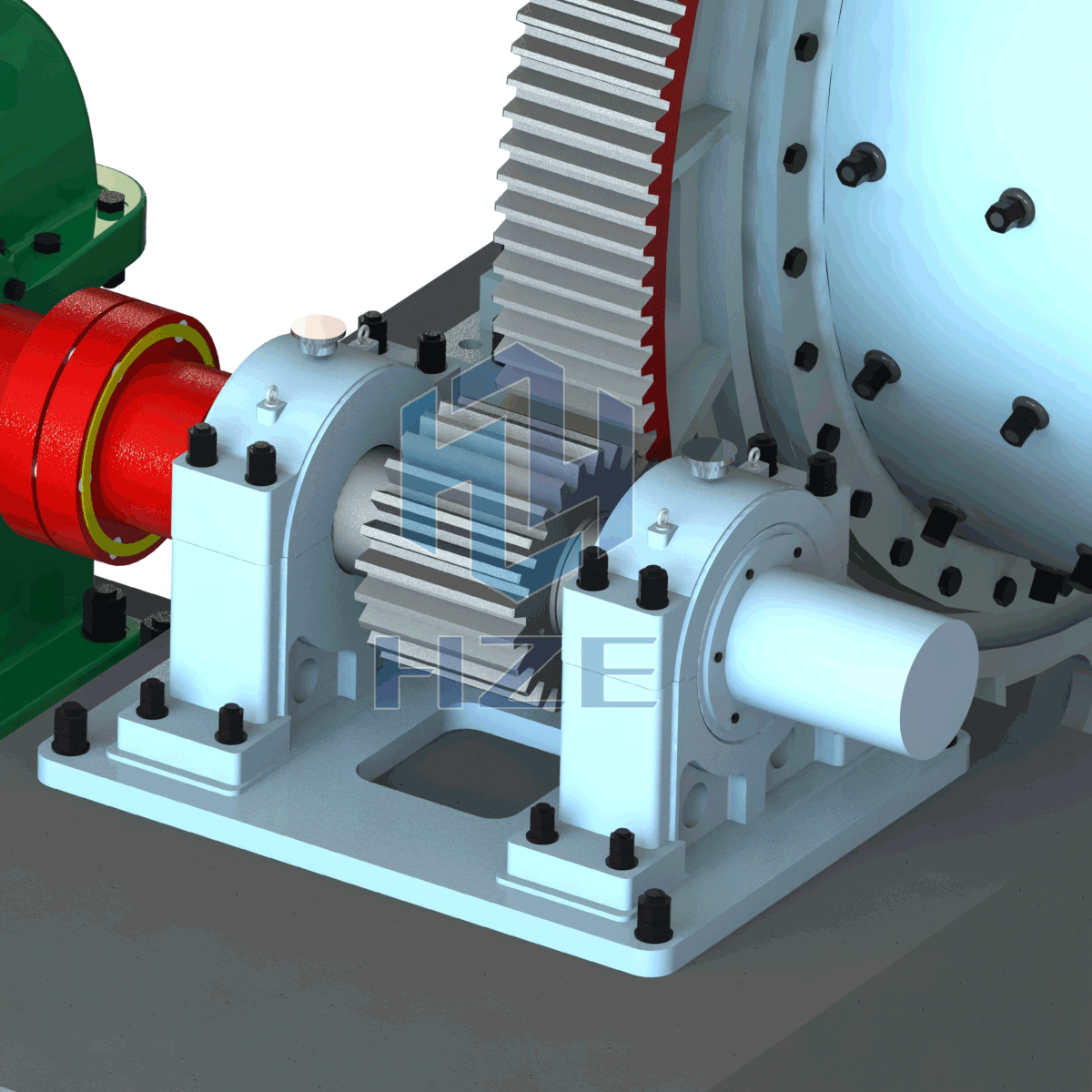

The big diameter ball mills have the inching driving device for easy starting and convenient maintenance.

The air forced grease spaying atomizer ensures the perfect lubrication of the pinion and girth gear.

Application Scope

The overflow ball mill can be used for primary grinding or re-grinding for the expected particle size.

Ball mill is one of the most commonly used mining equipment, which is widely used in mineral processing, construction materials, silicate and chemical industries. In the production of small scale, medium scale or large scale mineral processing Plants, it is generally used as the grinding machine for metal ores of gold, silver, copper, lead, zinc, nickel, manganese, iron, molybdenum, chromium, tin and others, as well as limestone, barite, quartz, graphite, feldspar, fluorspar, etc.

Technical Parameters

|

Model |

Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model |

Power (kW) |

Effective Volume (m3) |

Max. Ball Load (t) |

Weight (kg) |

|

MQYs0918 |

900 |

1800 |

Y225M-8 |

22 |

0.9 |

1.7 |

5496 |

|

MQYs1212 |

1200 |

1200 |

Y250M-8 |

30 |

1.1 |

2.0 |

11598 |

|

MQYs1224 |

1200 |

2400 |

YR280S-8 |

55 |

2.2 |

4.1 |

12489 |

|

MQYs1515 |

1500 |

1500 |

JR115-8 |

60 |

2.2 |

4.1 |

13841 |

|

MQYs1530 |

1500 |

3000 |

JR125-8 |

95 |

5 |

9.3 |

18801 |

|

Model |

Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model |

Power (kW) |

Effective Volume (m3) |

Max. Ball Load (t) |

Weight (kg) |

|

MQYs2122 |

2100 |

2200 |

JR128-8 |

155 |

6.6 |

12.3 |

45510 |

|

MQYs2130 |

2100 |

3000 |

JR137-8 |

210 |

9 |

16.7 |

45920 |

|

MQYs2136 |

2100 |

3600 |

JR137-8 |

210 |

10.8 |

20.1 |

52130 |

|

MQYs2145 |

2100 |

4500 |

JR148-6 |

310 |

13.5 |

25.1 |

58410 |

|

MQYs2430 |

2400 |

3000 |

JR1410-8 |

280 |

12.1 |

22.5 |

65996 |

|

MQYs2721 |

2700 |

2100 |

JR1410-8 |

280 |

10.7 |

19.9 |

63010 |

|

MQYs2736 |

2700 |

3600 |

TDMK400-32 |

400 |

18.4 |

34.2 |

96697 |

|

MQYs2740 |

2700 |

4000 |

TDMK400-32 |

400 |

20.4 |

37.9 |

78930 |

|

MQYs3230 |

3200 |

3000 |

TDMK500-36 |

500 |

21.8 |

40.5 |

107740 |

|

MQYs3245 |

3200 |

4500 |

TDMK630-36 |

630 |

32.8 |

61.0 |

132362 |

|

MQYs3254 |

3200 |

5400 |

TM1000-36 |

1000 |

39.4 |

73.3 |

141121 |

|

Model |

Cylinder Diameter (mm) |

Cylinder Length (mm) |

Motor Model |

Power (kW) |

Effective Volume (m3) |

Max. Ball Load (t) |

Weight (kg) |

|

MQYs3645 |

3600 |

4500 |

TM1000-36 |

1000 |

41.8 |

77.7 |

158147 |

|

MQYs3650 |

3600 |

5000 |

TM1250-40 |

1250 |

46.4 |

86.3 |

165200 |

|

MQYs3660 |

3600 |

6000 |

TM1250-40 |

1250 |

55 |

102.3 |

187321 |

|

MQYs3690 |

3600 |

9000 |

TDK1800-30 |

1800 |

83 |

154.4 |

212410 |

|

MQYs3867 |

3800 |

6700 |

TDK1500-30 |

1500 |

70 |

130.2 |

196198 |

|

MQYs4067 |

4000 |

6700 |

TDK1600-30 |

1600 |

78 |

145.1 |

207256 |

|

MQYs4561 |

4500 |

6100 |

TDK2200-30 |

2200 |

93 |

173.0 |

238321 |

DOWNLOAD

DOWNLOAD