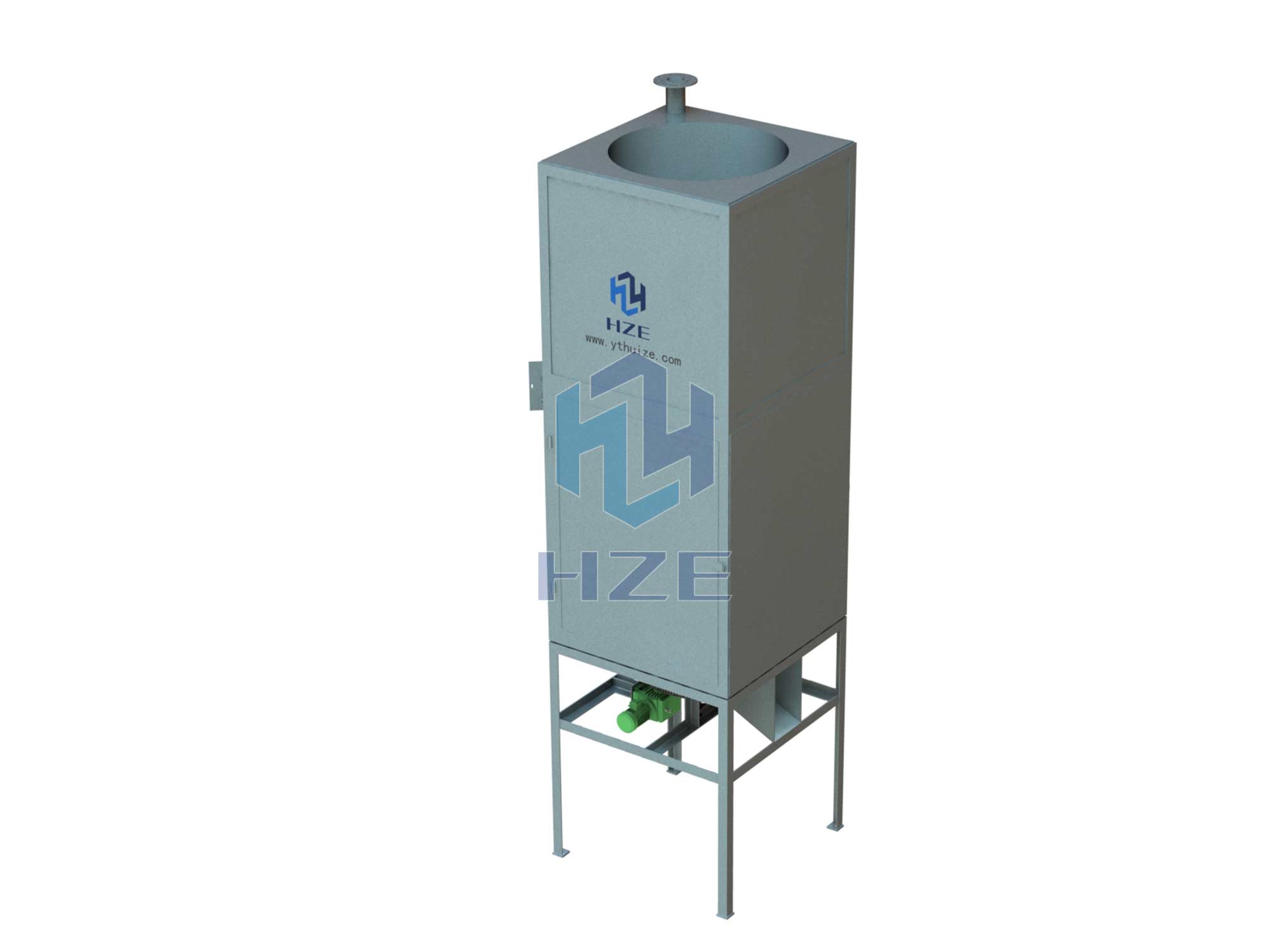

Vertical Activated Carbon Regenerator

Working Principle

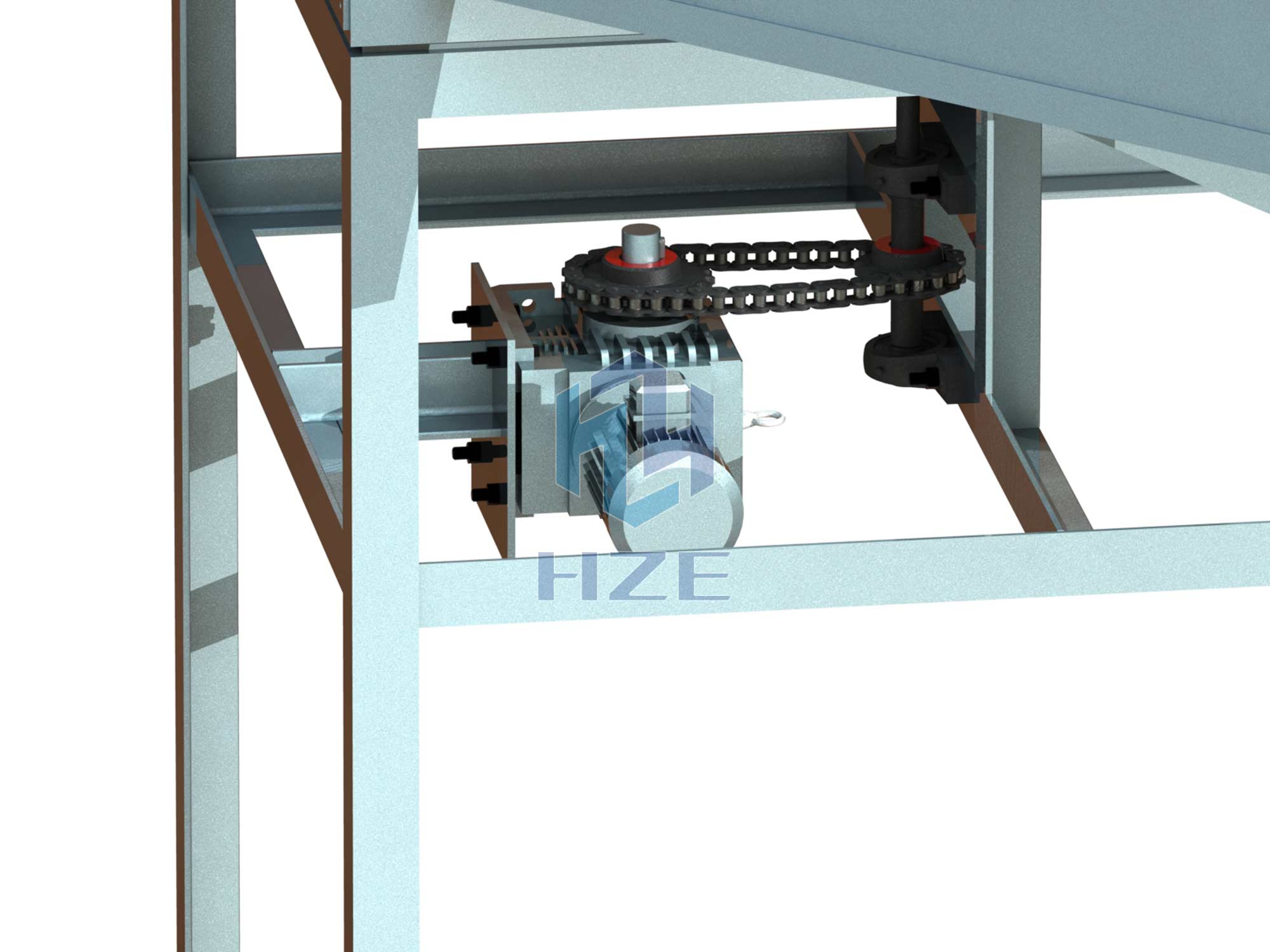

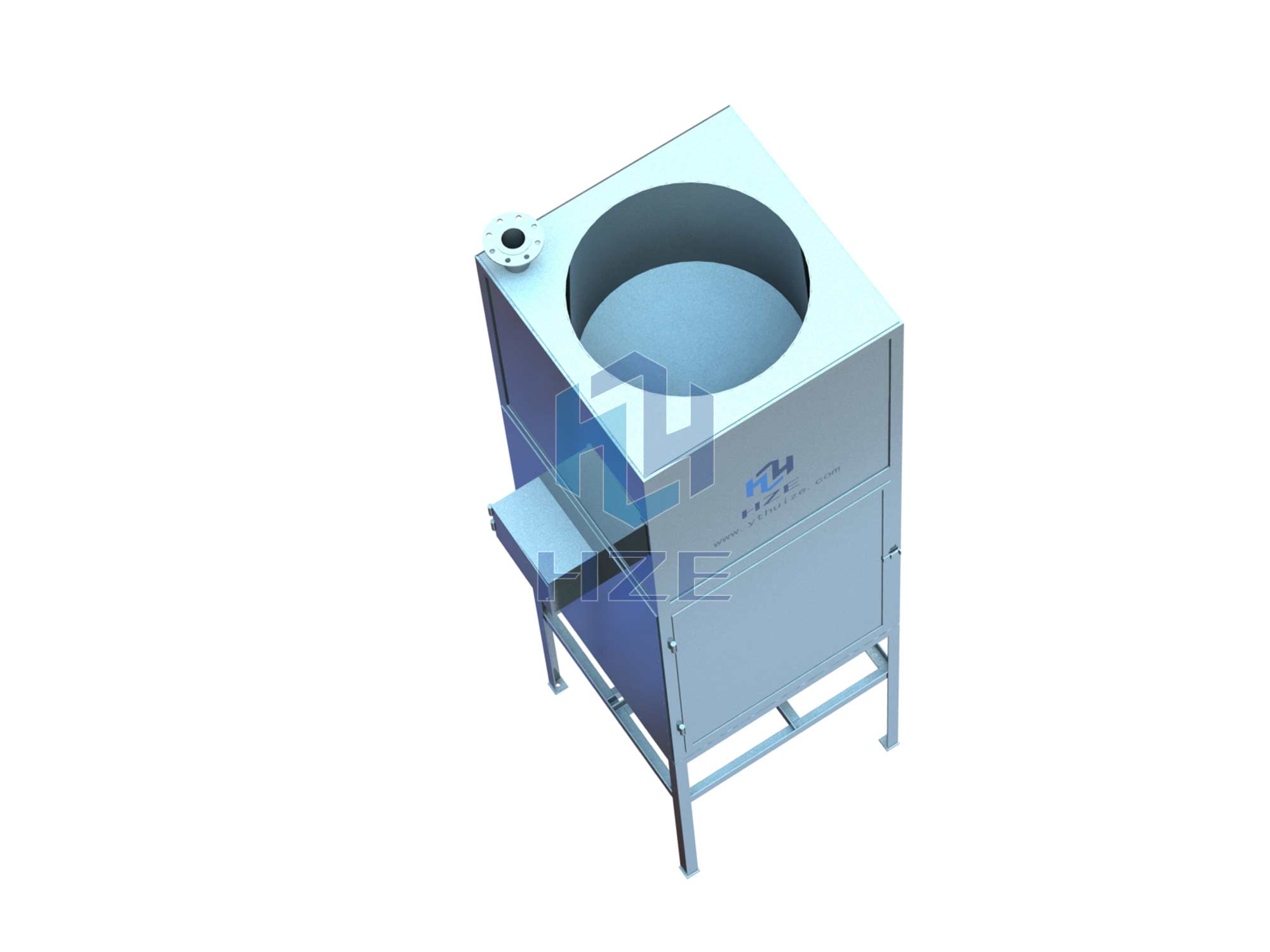

The activated carbon stored in the hopper is fed into the generator chamber and forms the carbon stream layer. The carbon generation capacity will be controlled automatically by the discharge device. The residence time of the carbon in the chamber changes with the moisture of the activated carbon and it is usually 15-25 minutes. The current will be input into the panel through the circuit then pass the carbon stream layer to make the carbon heating by itself to achieve drying, activation and carbonization. The temperature control system composed of temperature measuring sensors and temperature controller makes temperature in the furnace kept at 700-850 ℃ which is the optimal temperature. Steam is generated from water kept on the surface of the carbon in the high temperature chamber and it flows pass the surface of the hot carbon continuously to regenerate the carbon. The proper moisture of carbon for regeneration is approximately 5%.

Basing on the characteristics of carbon and water, the activated carbon regenerator can execute drying, high-temperature carbonization and activation continuously at same time during automatic control circuit runs. Meanwhile, it always keeps the micro positive voltage in the whole regeneration system. After regeneration, the iodine value of the carbon can be restored to more than 95%. The system has the features of high regeneration rate, low consumption, low carbon consumption and reliable operation.

Applications

The automatic activated carbon regenerator is suitable for the fire regeneration of various fine activated carbon made from coconut shell charcoal, apricot charcoal and other materials and is widely used in CIP processing circuit, CIL processing circuit, vat leach circuit, heap leach circuit of the gold industry and water treatment industry, etc.

Technical Parameters

|

Model |

Capacity (kg/d) |

Power (kW) |

Voltage (v) |

Adsorption Recovery Rate of Carbon (Iodine meter Measurement) |

Carbon Consumption Rate |

Carbon Residence (min) |

|

HZL800 |

600-800 |

50 |

380 |

90-95% |

<2% |

15-25 |

|

HZL1600 |

1000-1600 |

80 |

380 |

90-95% |

<2% |

15-25 |

|

HZL2500 |

2000-2500 |

120 |

380 |

90-95% |

<2% |

15-25 |

DOWNLOAD

DOWNLOAD