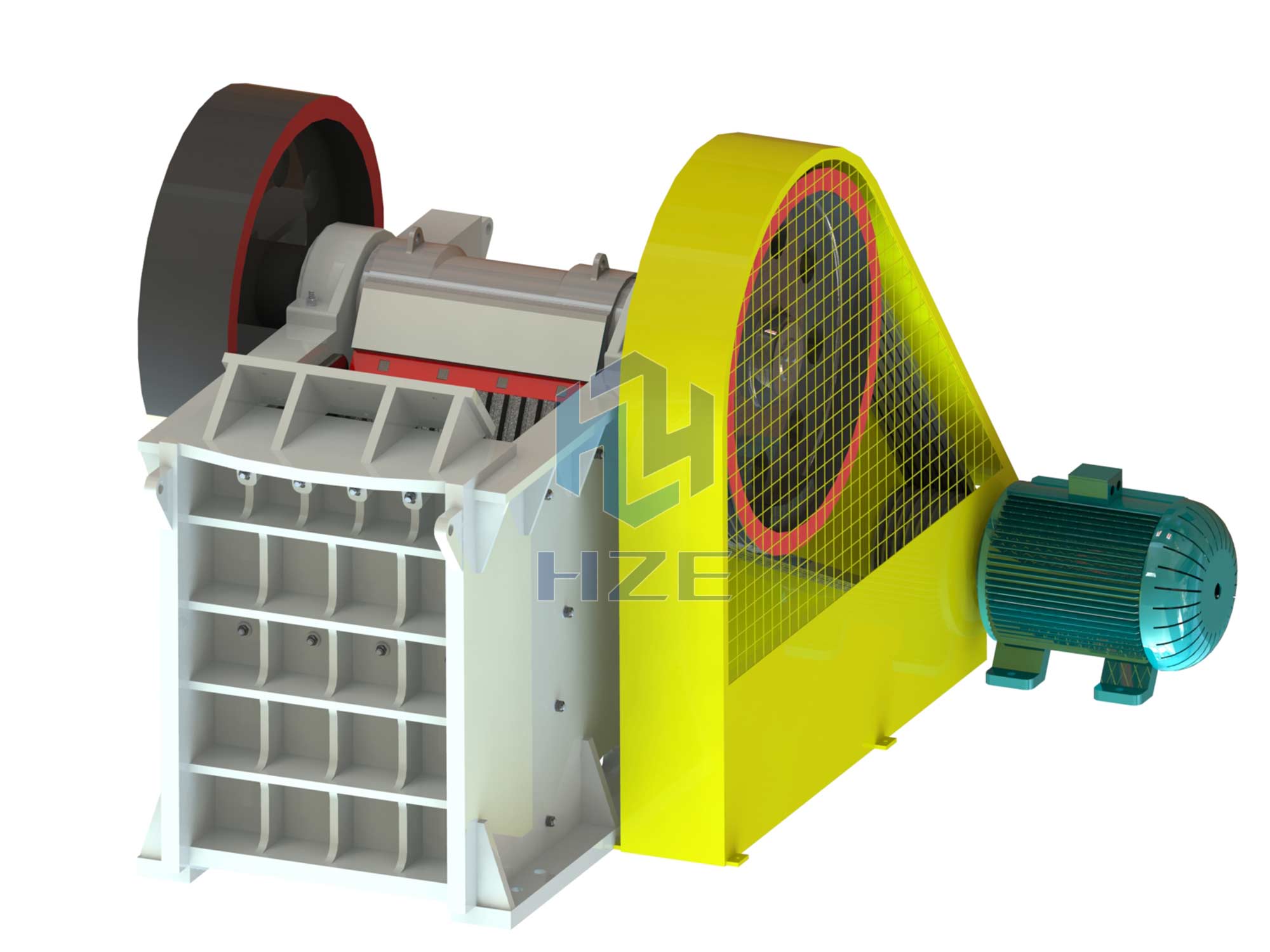

Jaw Crusher

Working Principle

The materials fall into the crushing chamber consisting of a fixed jaw and a movable jaw. Due to the periodic reciprocating swing of the movable jaw, when the movable jaw is close to the fixed jaw plate, the materials are crushed, split and broken. When the movable jaw leaves the fixed jaw, the materials broken to less than the size of the discharge outlet are discharged out of the crushing chamber by their gravity. The materials located in the upper crushing chamber have not been crushed to a small enough size, and then fall into the lower chamber to be further crushed.

Features

Large crushing ratio, optimized crushing chamber; high efficiency; slight vibration; good reliability.

Application Scope

Jaw crusher is one of the most commonly used mining equipment, which is widely used in mineral processing, construction materials, silicate and chemical industries. In the production of small scale, medium scale or large scale mineral processing plants, it is generally used as the primary and secondary crushing machine to crush hard or medium hard metal ores of gold, silver, copper, lead, zinc, nickel, manganese, iron, molybdenum, chromium, tin and others, as well as stone, rock, granite, limestone, barite, quartz, graphite, feldspar, fluorspar, etc.

Technical Parameters

Small Size

|

Model |

Feeding Inlet L×W (mm) |

Discharging Outlet (mm) |

Max. Feeding Size (mm) |

Capacity (t/h) |

Rotation Speed (r.p.m) |

Power (kW) |

|

PE150×250 |

150×250 |

10-40 |

125 |

2~6 |

300 |

5.5 |

|

PEX150×500 |

150×500 |

10-40 |

120 |

6~28 |

325 |

15 |

|

PEX150×750 |

150×750 |

10-40 |

8~35 |

320 |

||

|

PE200×350 |

200×350 |

10-50 |

160 |

6~10 |

285 |

7.5 |

|

PE250×400 |

250×400 |

20-60 |

210 |

5~20 |

275 |

15 |

Mideum Size

|

Model |

Feeding Inlet L×W (mm) |

Discharging Outlet (mm) |

Max. Feeding Size (mm) |

Capacity (t/h) |

Rotation Speed (r.p.m) |

Power (kW) |

|

PEX200×1000 |

200×1000 |

15-40 |

160 |

12~50 |

330 |

22 |

|

PEX250×750 |

250×750 |

20-60 |

210 |

10~45 |

320 |

30 |

|

PEX250×1000 |

250×1000 |

20-50 |

15~50 |

330 |

30 |

|

|

PEX250×1200 |

250×1200 |

20-60 |

20~60 |

320 |

45 |

|

|

PE400×600 |

400×600 |

40-100 |

350 |

14~36 |

275 |

30 |

|

PEX500×750 |

500×750 |

50-120 |

400 |

30~80 |

250 |

45 |

Big Size

|

Model |

Feeding Inlet L×W (mm) |

Discharging Outlet (mm) |

Max. Feeding Size (mm) |

Capacity (t/h) |

Rotation Speed (r.p.m) |

Power (kW) |

|

PE600×900 |

600×900 |

75-200 |

480 |

56~192 |

250 |

75 |

|

PE750×1060 |

750×1060 |

80-235 |

630 |

108~256 |

250 |

90 |

|

PE900×1200 |

300×1300 |

95-265 |

750 |

186~398 |

200 |

110 |

DOWNLOAD

DOWNLOAD