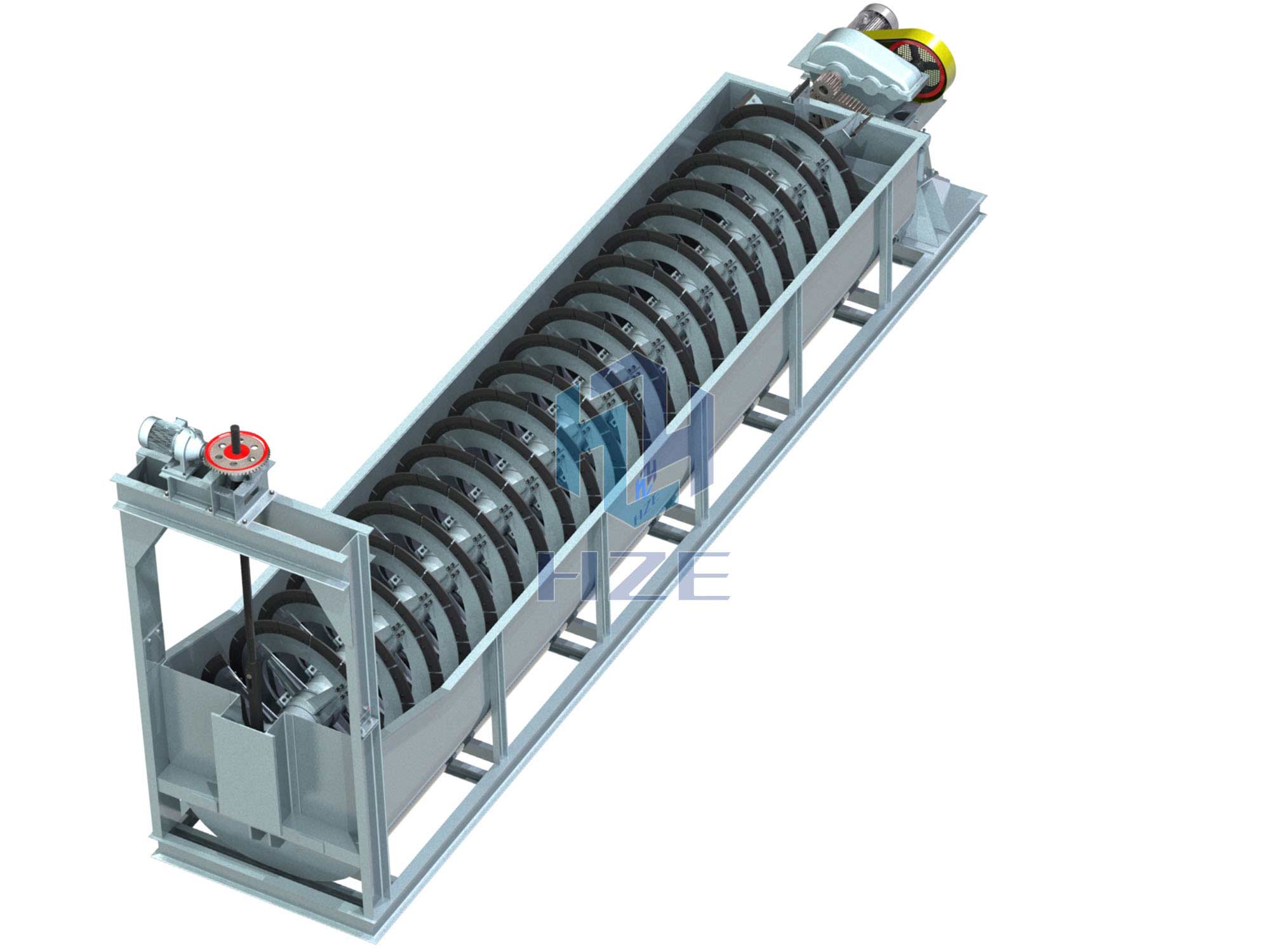

Spiral Classifier

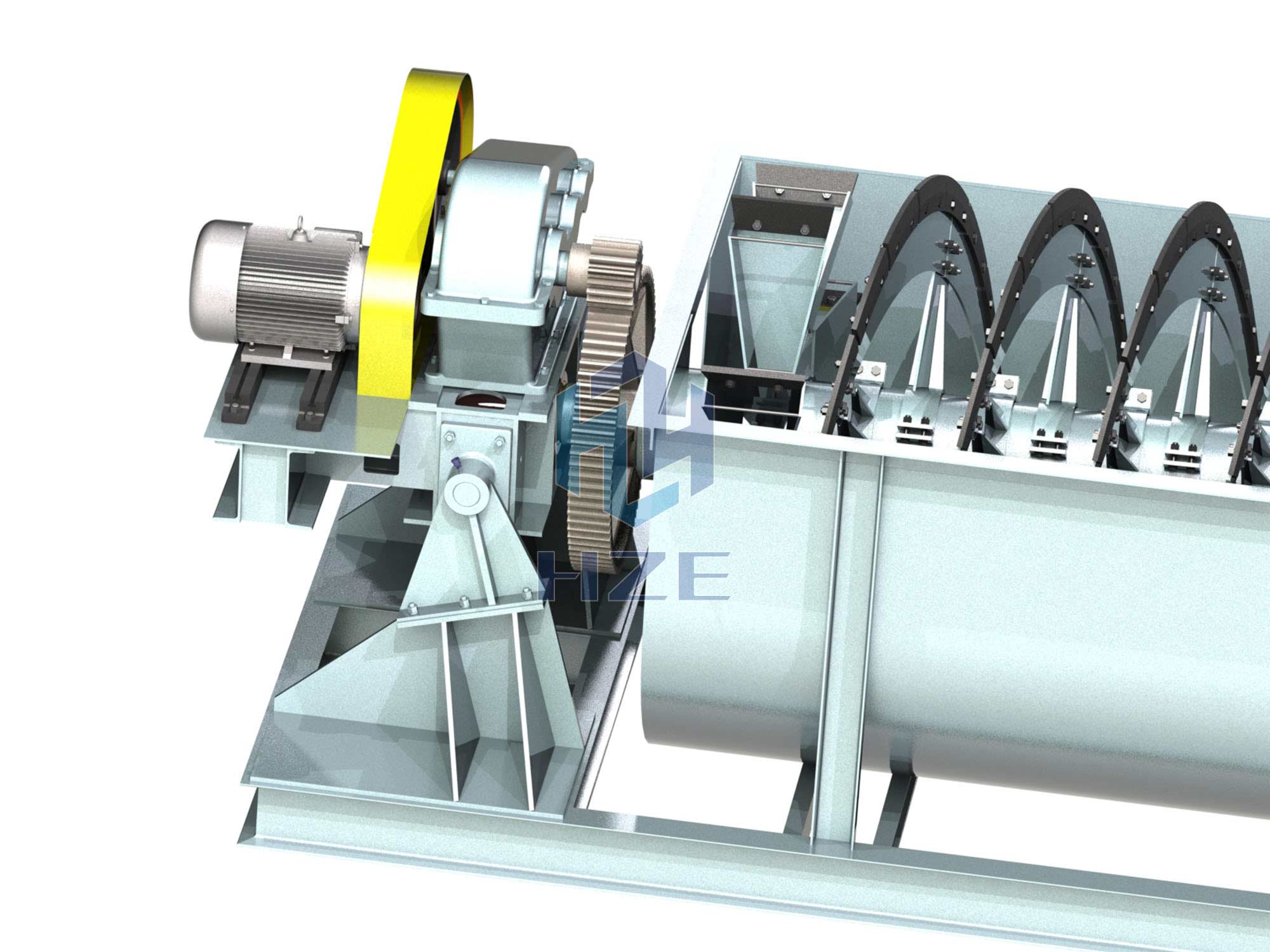

Working Principle

The ground slurry is fed into trough from the inlet located in the middle of the settling area, and the slurry classification depression area is under the inclined trough. The spiral with low-speed rotation stirs the slurry, so that the fine particles suspended in the upper flow into overflow weir and overflow. Meanwhile, the coarse particles sink to the bottom of the trough, and then they are delivered to the outlet by the spiral and discharge as particles returned.

Features

The whole spiral of overflow end is sunk under the liquid surface of the settling area with larger area and depth.

Automotive lifting device for particles returned is added on the particles returned end, and the scoop feeder is canceled in the ball mill.

1-1.5 degree of electricity can generally be saved per ton of ore.

Frequent maintenance of big spoon bit is avoided.

Uneven impact on large and small gear is retarded.

Application Scope

Suitable for coarse size classification.

Spiral classifier is one of the most commonly used mining equipment, which is widely used in mineral processing, construction materials, silicate and chemical industries. In the production of small scale, medium scale or large scale mineral processing plants, it is generally used as the classifying machine or washing machine for metal ores of gold, silver, copper, lead, zinc, nickel, manganese, iron, molybdenum, chromium, tin and others, as well as limestone, barite, quartz, graphite, feldspar, fluorspar, etc.

Technical Parameters

Single Spiral

|

Model |

Spiral Speed (r.p.m) |

Overflow Capacity (t/d) |

Spiral Diameter (mm) |

Trough Length (mm) |

Slope Degree (°) |

Motor Power (kW) |

|

FG(T)-300 |

7.7 |

10-30 |

300 |

3900 |

14-18.5 |

2.2 |

|

FG(T)-500 |

8 |

21-75 |

500 |

4390 |

||

|

FG(T)-750 |

7.8 |

31-165 |

750 |

5500 |

3 |

|

|

FG(T)-1000 |

6.7 |

85 |

1000 |

6500 |

5.5 |

|

|

FG(T)-1200 |

5,6,7 |

150 |

1200 |

6500 |

5.5 |

|

|

FG(T)-1500 |

2.5,4,6 |

235 |

1500 |

8265 |

7.5 |

|

|

FG(T)-2000 |

3.5,5.5 |

400 |

2000 |

8400 |

11;15 |

|

|

FG(T)-2400 |

3.6 |

580 |

2400 |

9130 |

15 |

|

|

FG(T)-3000 |

3.2 |

890 |

3000 |

12500 |

22 |

Double Spirals

|

Model |

Spiral Speed (r.p.m) |

Overflow Capacity (t/d) |

Spiral Diameter (mm) |

Trough Length (mm) |

Slope Degree (°) |

Motor Power (kW) |

|

2FG-1200 |

5,6,7 |

310 |

1200 |

6500 |

14-18.5 |

5.5×2 |

|

2FG-1500 |

2.5,4,6 |

460 |

1500 |

8265 |

7.5×2 |

|

|

2FG-2000 |

3.6,5.5 |

750 |

2000 |

8400 |

15×2 |

|

|

2FG-2400 |

3.63 |

1160 |

2400 |

9130 |

22×2 |

|

|

2FG-3000 |

3.2 |

1785 |

3000 |

12500 |

30×2 |

DOWNLOAD

DOWNLOAD