Small Scale Modular Gold Processing Plant

The following situations or difficulties are common in plenty of small gold mines:

(1) Geological exploration is inadequate, proven resource reserves are small, scattered veins are narrower or shorter, which are not suitable for large-scale mining;

(2) The mine owners lack sufficient funds to invest in medium and large-scale mines and need to make profits from small-scale mining and processing.

(3) The mine traffic is inconvenient and not suitable for large-scale heavy equipment transportation, materials and power supply are shortage;

(4) The lack of water resources in mining areas cannot meet the continuous demand of water for medium and large-scale plant production;

(5) There are a large number of artisanal or small-scale miners in the mining area who generally use sluice boxes, amalgamation with mercury or other old processing to recover gold, which is inefficient, low recovery, harms health and environmental pollution.

(6) Some mine owners hope to transfer their processing plants to another mining area after a few months or one or two years of production. They do not want to repeat to set up new plants.

(7) Small-scale mine owners hope to obtain the best general solution to recover gold directly by quickly setting up a processing plant for production and minimizing tedious work;

(8) Many small-scale artisanal miners in the mining area hope that there will be a small-scale processing plant in the area. They send ores for processing in the plant for making better profits than the original processing by their selves.

(9) Some mine owners who have mines with large reserves of resources worry that the risk of directly establishing large-scale processing plant is too high. They need to establish a small-scale plant as pilot to verify the actual processing effect and conduct economic evaluation, so as to provide the basis for final decision-making.

(10) Previously processed tailings still contain valuable gold. The mining investors want to quickly build a small-scale processing plant with low investment to recover as much gold as possible from tailings under the lowest production costs.

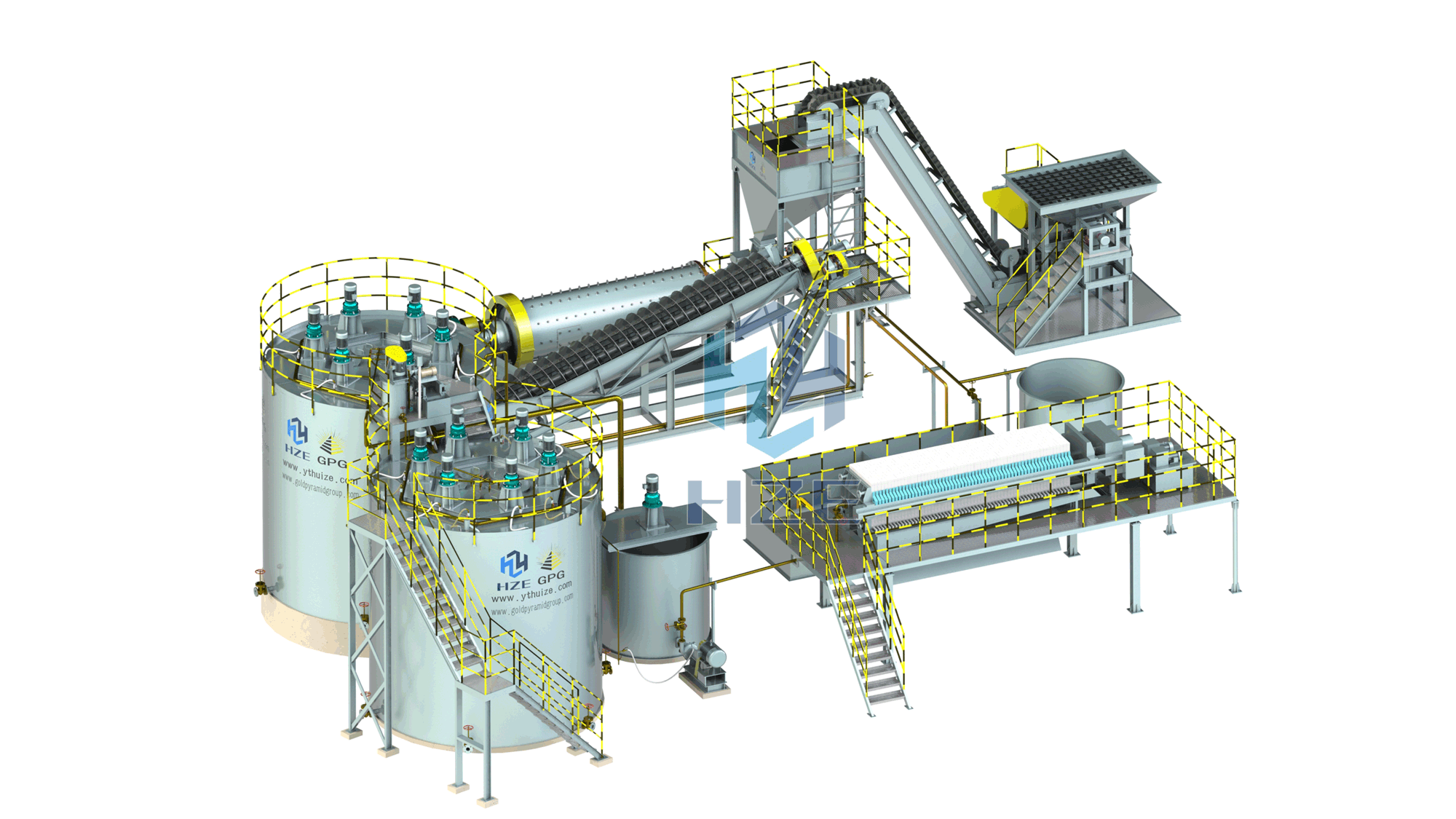

Aiming at the demand of small-scale gold mining and processing, HZE design and manufacture the small-scale modular gold processing plants to recover gold from rocks, quartz veins, alluvial deposits or tailings by gravity separation, flotation, cyanidation or combination processing. Excellent solutions, advanced technology, complete functions, reliable and safe equipment, compact structure, unconditional installation locations, low-cost investment and simple construction make the modular processing plants become the shining stars of flexible, fast and efficient recovery of gold and be favored by more and more mine owners.

The small-scale modular concentrator has achieved the following targets:

(1) Maximizing the utilization of mineral resources ensures high recovery and economic benefits;

(2) The advanced technology and processing are adopted to get rid of the harmful chemicals such as mercury completely and protect human health and natural environment;

(3) Energy, water and consumables are saved, the number of operators is reduced, the capital of investment and the cost of production are decreased.

(4) Installation is fast, the operation is easy, running is reliable, and different functional modules are combined freely to achieve the maximum recovery of gold.

(5) Minimal civil work requirements and the construction period reduced very much.

(6) It is easy to containerized, shipped or transferred to another location and reassembled, even in the most remote locations in the world.

GENERAL FUNCTIONAL MODULES

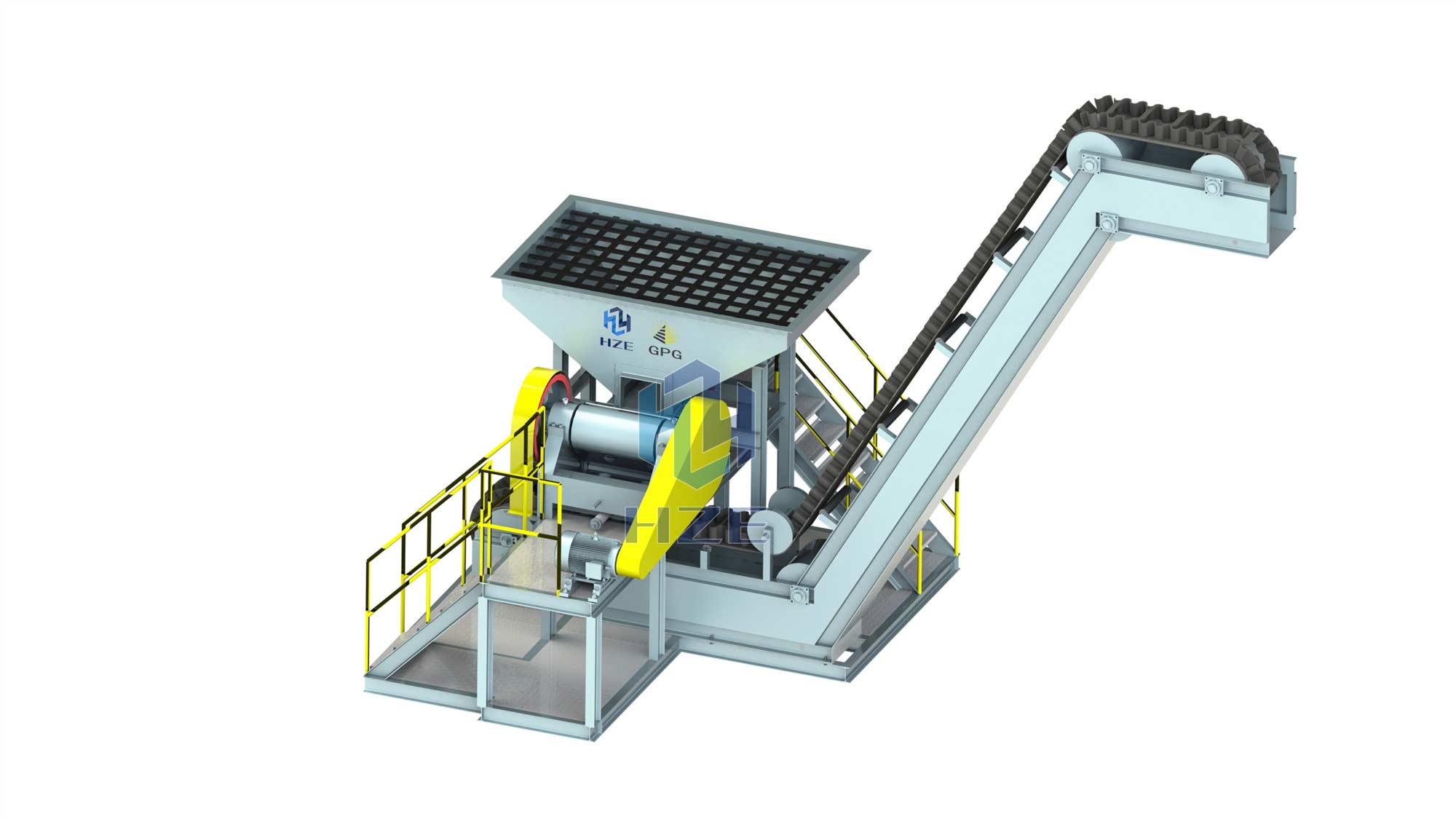

Crushing module

The rocks are crushed to the qualified particle size for grinding. The module is composed of hoppers, crushers, belt conveyors, feeders and so on.

The ores are usually crushed in two stages. According to the actual situation of the site, the primary crusher can be mounted in the mining area or the processing plant. The crusher is usually driven by a diesel engine if it is located in the mining area.

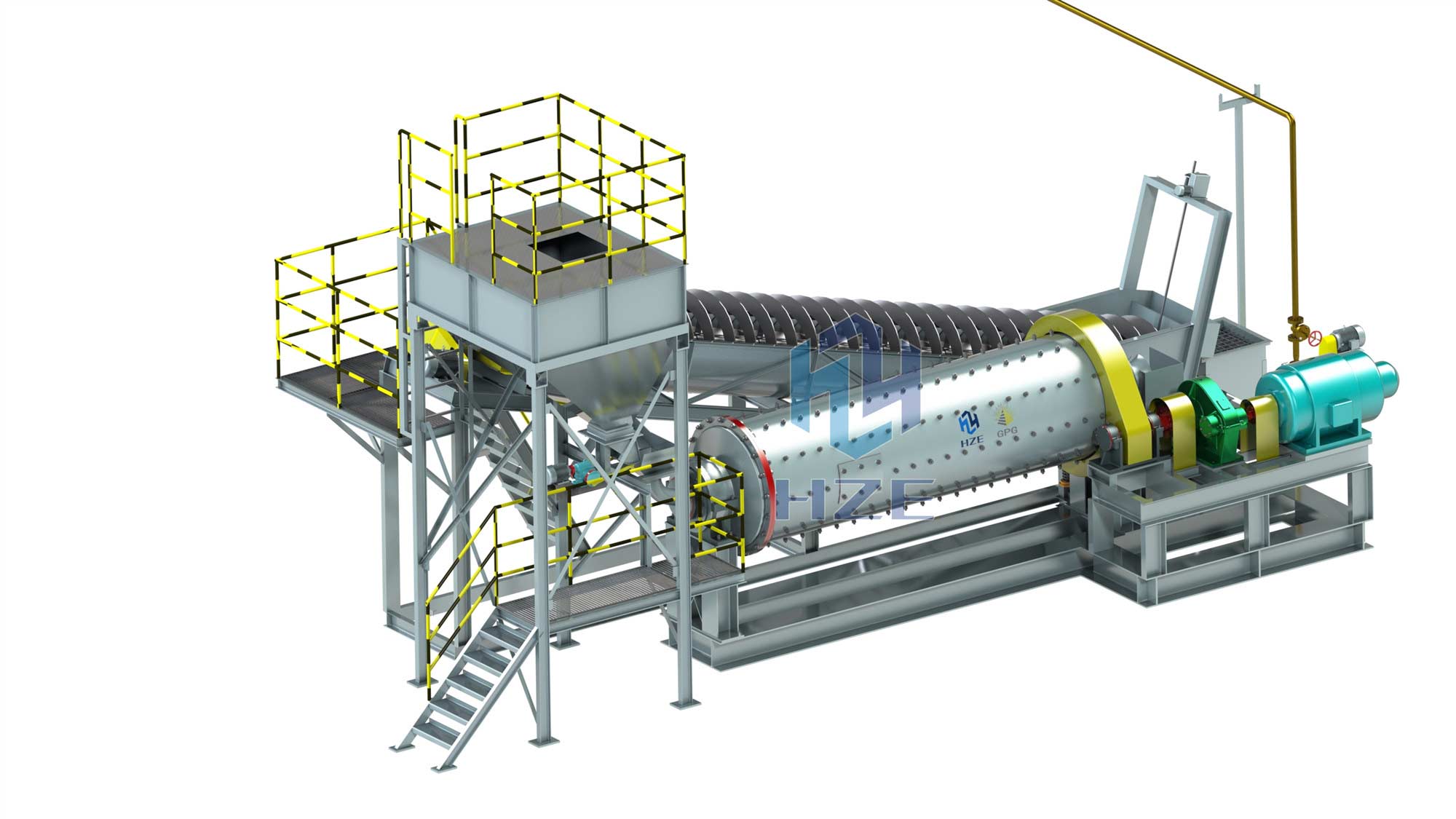

Grinding and classification unit

The closed-circuit grinding and classification system consisting of the ball mill and spiral classifier can liberate ore into the suitable particles for recovering gold. The unit can be adjusted to a closed-circuit system consisting of the ball mill, slurry pump and hydrocyclone if the customer demands.

The grinding and classification unit is amounted in the whole steel frame.

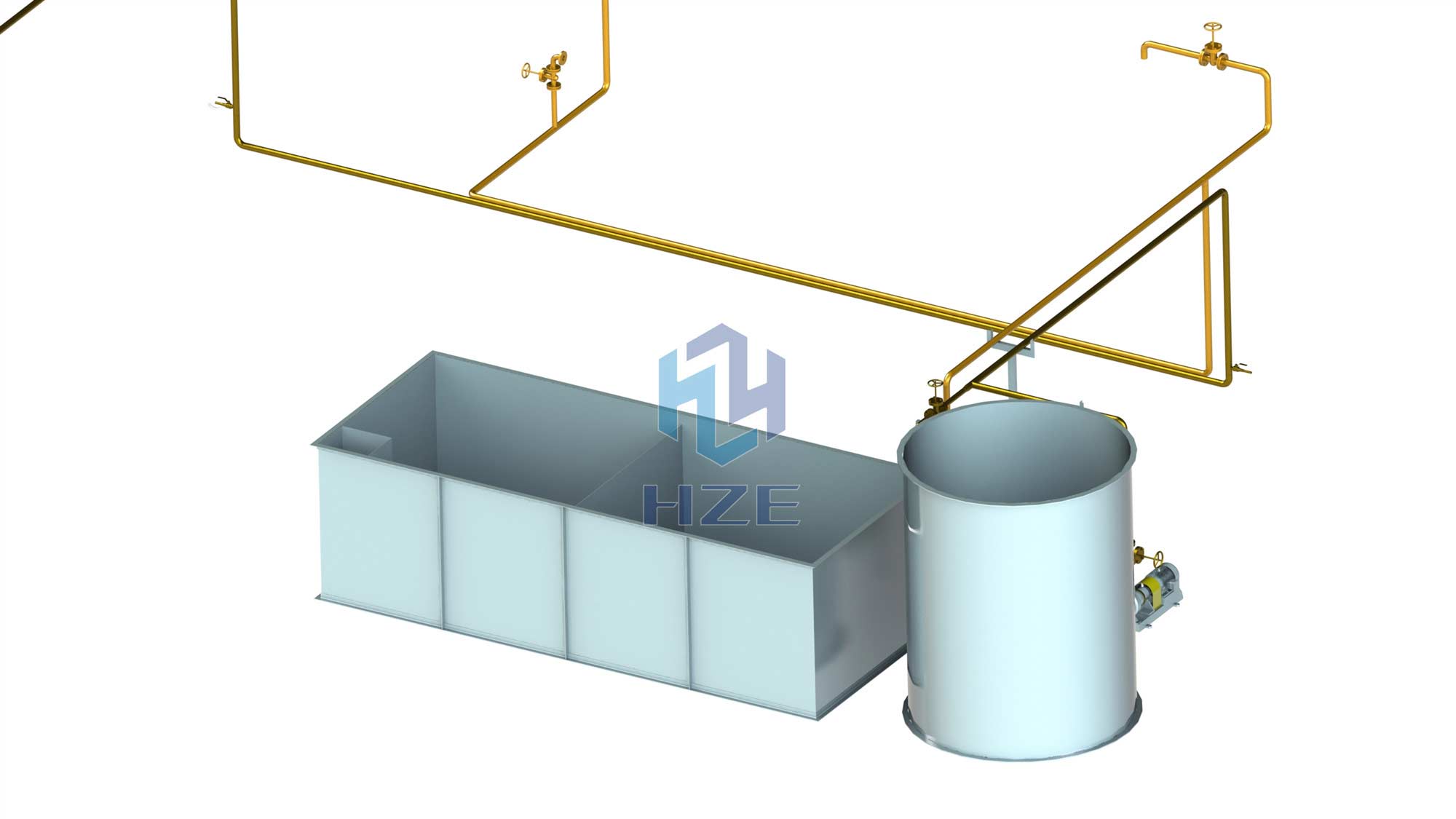

Water supply module

It is composed of the water tanks, water pumps and water supply pipeline. The optimized water balance is achieved by the controlled the utilization rate of water.

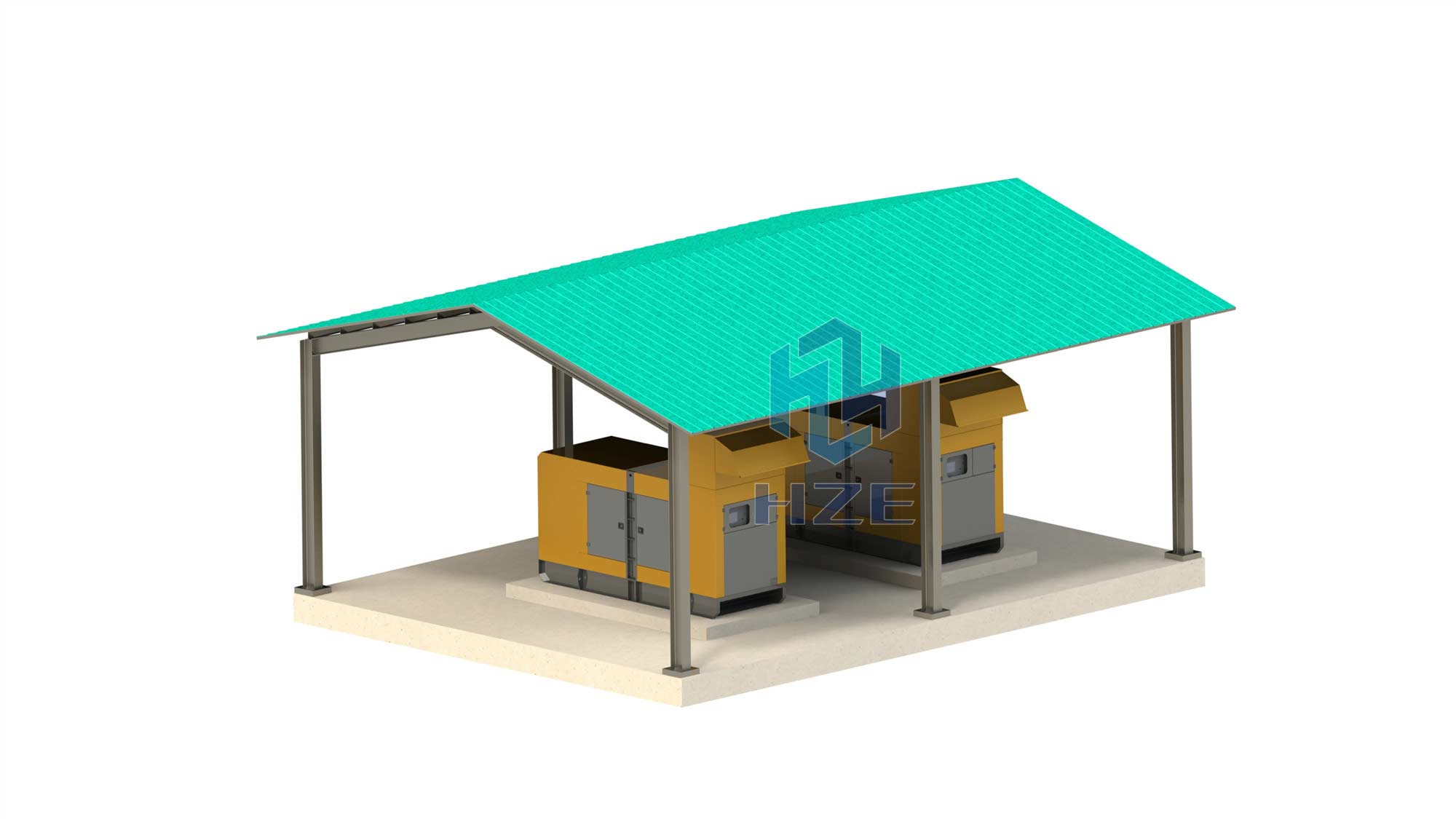

Power supply module

It is composed of the diesel generators, distribution devices and the starting panels and so on. The module is suitable for the areas with inconvenient traffic and shortage of the power grid.

SPECIAL MODULES

It is selected the general modules and the special modules to combine together to achieve maximum gold recovery.

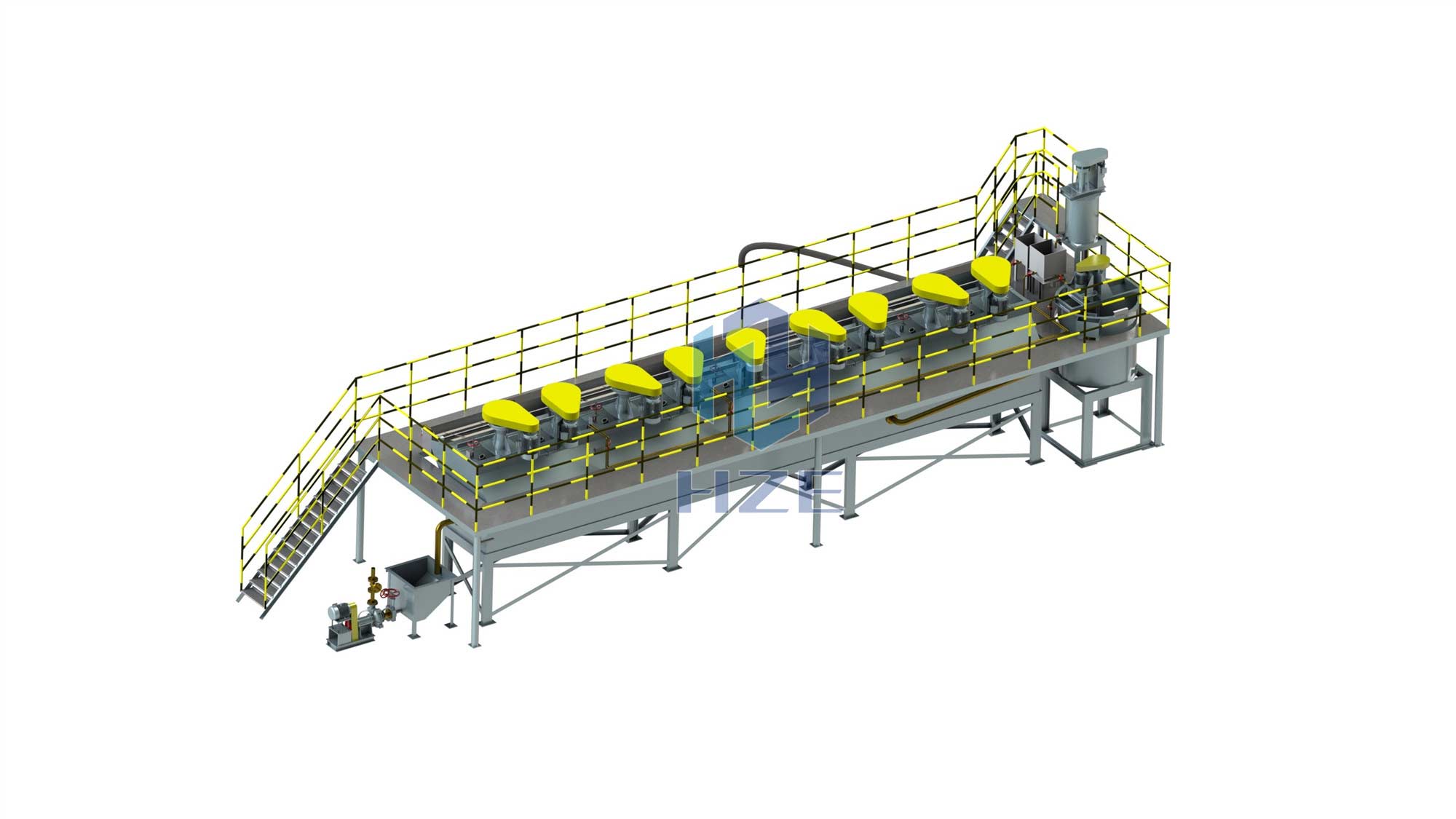

The commonly used special modules are gravity concentration module, flotation module and cyanide leaching module.