Ore Crushing Plant

Crushing Circuit and Equipment

Ores coming from open-pit or underground mining need to be broken to a certain size for the next processing such as gangue rejection and enrichment, grinding and further minerals separation.

According to the difference size of raw ore & crushed products and crushing capacity, crushing systems can be divided into open circuit and closed circuit. There is no screening machine in the open circuit process, and the closed circuit has vibrating screen to control product size. The crushing stages are named as primary crushing secondary crushing stage triple crushing and so on. Therefore, according to different capacity and requirements, the common equipment for different ore crushing stage is as follows:

Primary crushing: rotary crusher, jaw crusher, etc.

Secondary crushing: jaw crusher, cone crusher, hammer crusher, etc.

Fine crushing: cone crusher, hammer crusher, roller crusher, vertical shaft impact crusher, etc.

In the crushing process, other equipment commonly needed are hoppers, grizzlies, conveyors, feeders, vibrating screens, dust removal facilities, weighing facilities, protection facilities, etc.

Crushing Circuit Examples

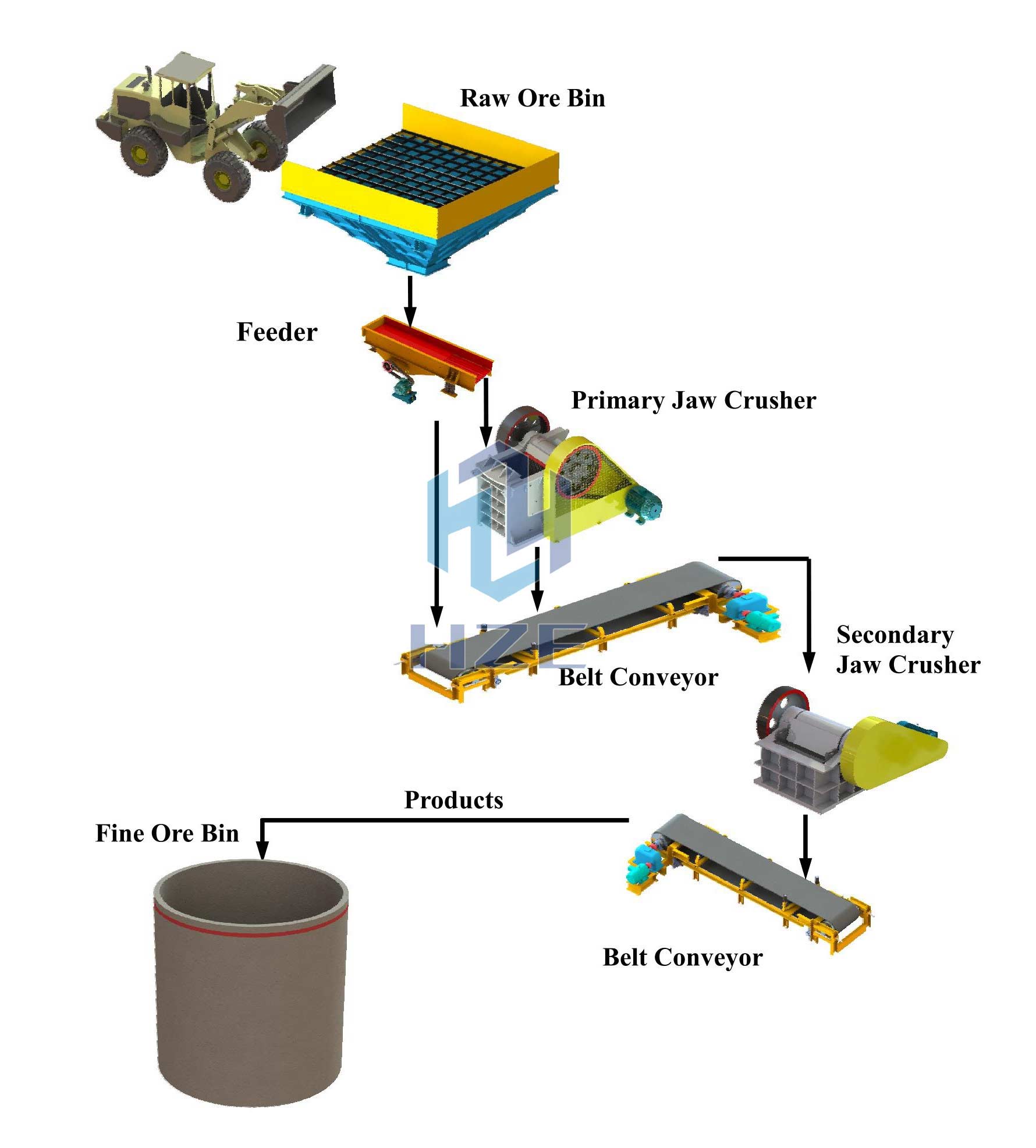

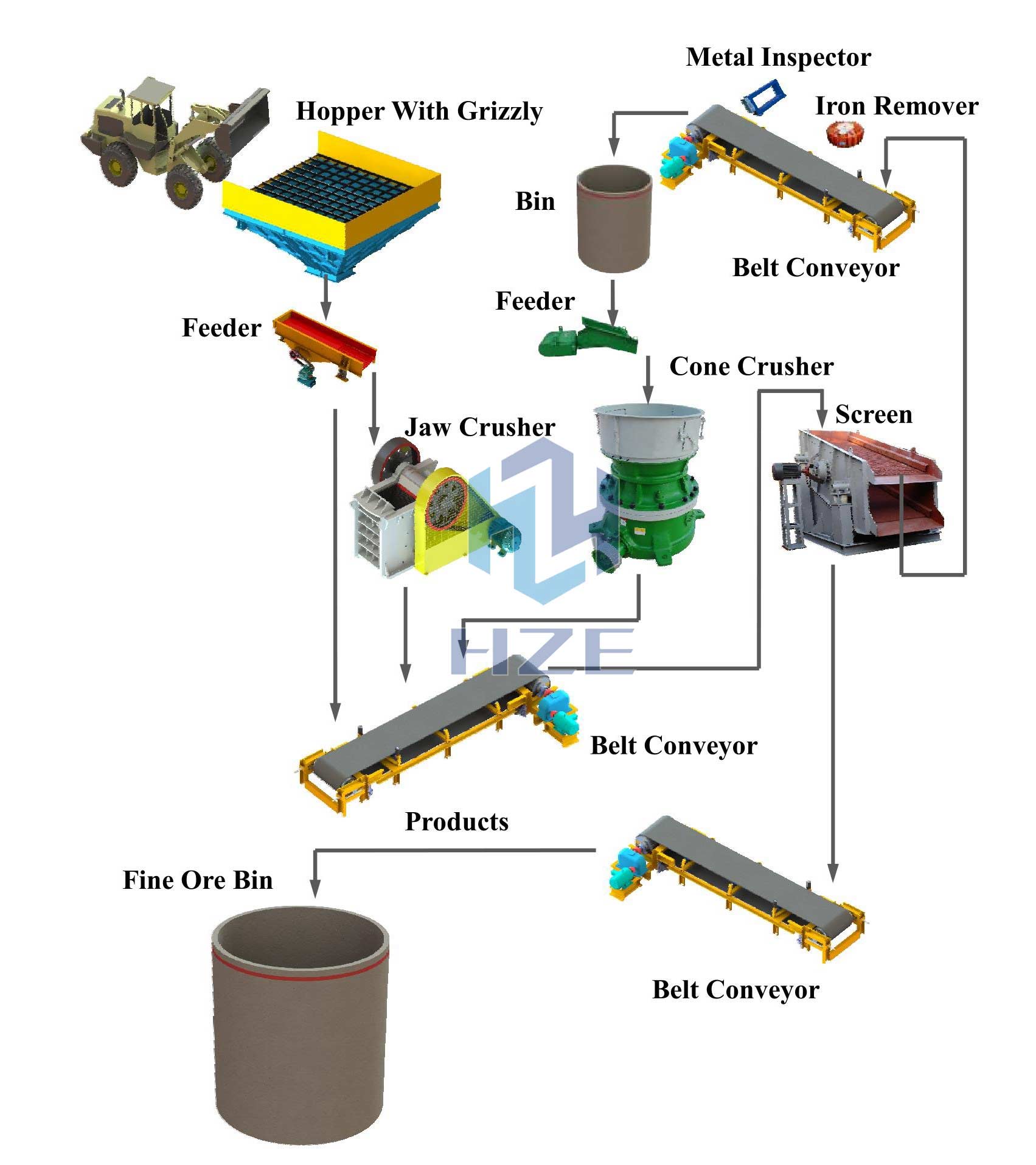

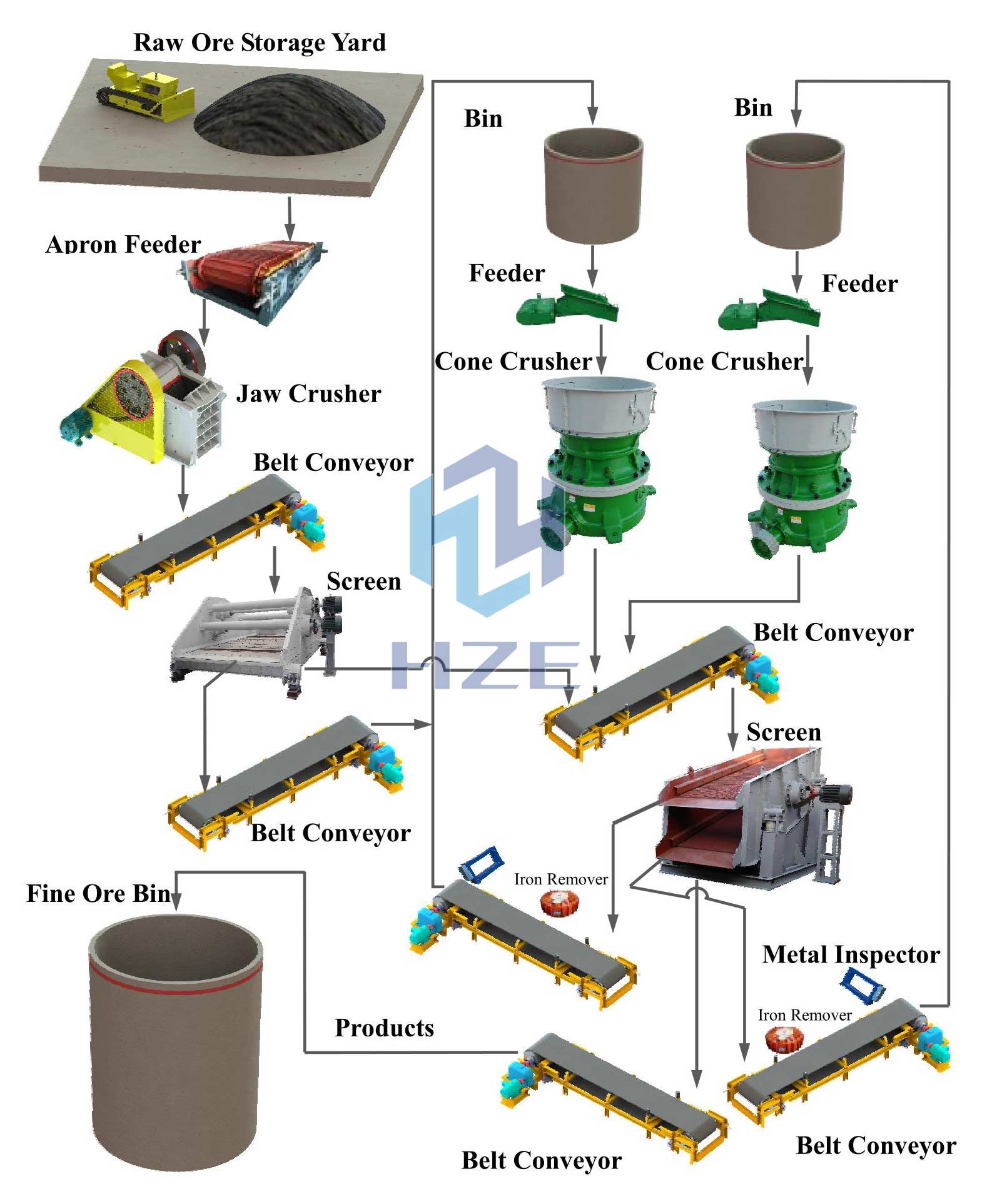

Many kinds of the designed crushing circuit are suitable for different crushing plants. Three circuit examples of crushing plants are following.

Open circuit of two crushing stages

Closed circuit of two crushing stages

Closed circuit of three crushing stages

Supplied Equipment and Services

HZE supply single crushing equipment for various hardness of different kinds of ores. Also HZE supply a complete set of solution for the crushing plants with small scale, medium scale or large scale, which included engineering design, equipment manufacturing and supply, logistics, installation, commissioning, training, trial production and so on to ensure advanced technology, perfect processing, efficient plant construction, reduced investment, environmental protection and maximum benefits.