Gold or Silver Heap Leach and CIC

For the leachable low-grade raw ore or tailings, the circuit of heap leach and CIC processes is a good idea if it is expected to reduce the investment and production cost of the processing plant.

The suitable crushed ore particles or tailings are piled into a heap on the geomembrane which prevents leakage. There are many of sprinklers for irrigation on the top of the heap. The raw materials should to be granulated or mixed with cement to enhance water permeability if the ore has too much slime/clay or the water permeability of materials is poor.

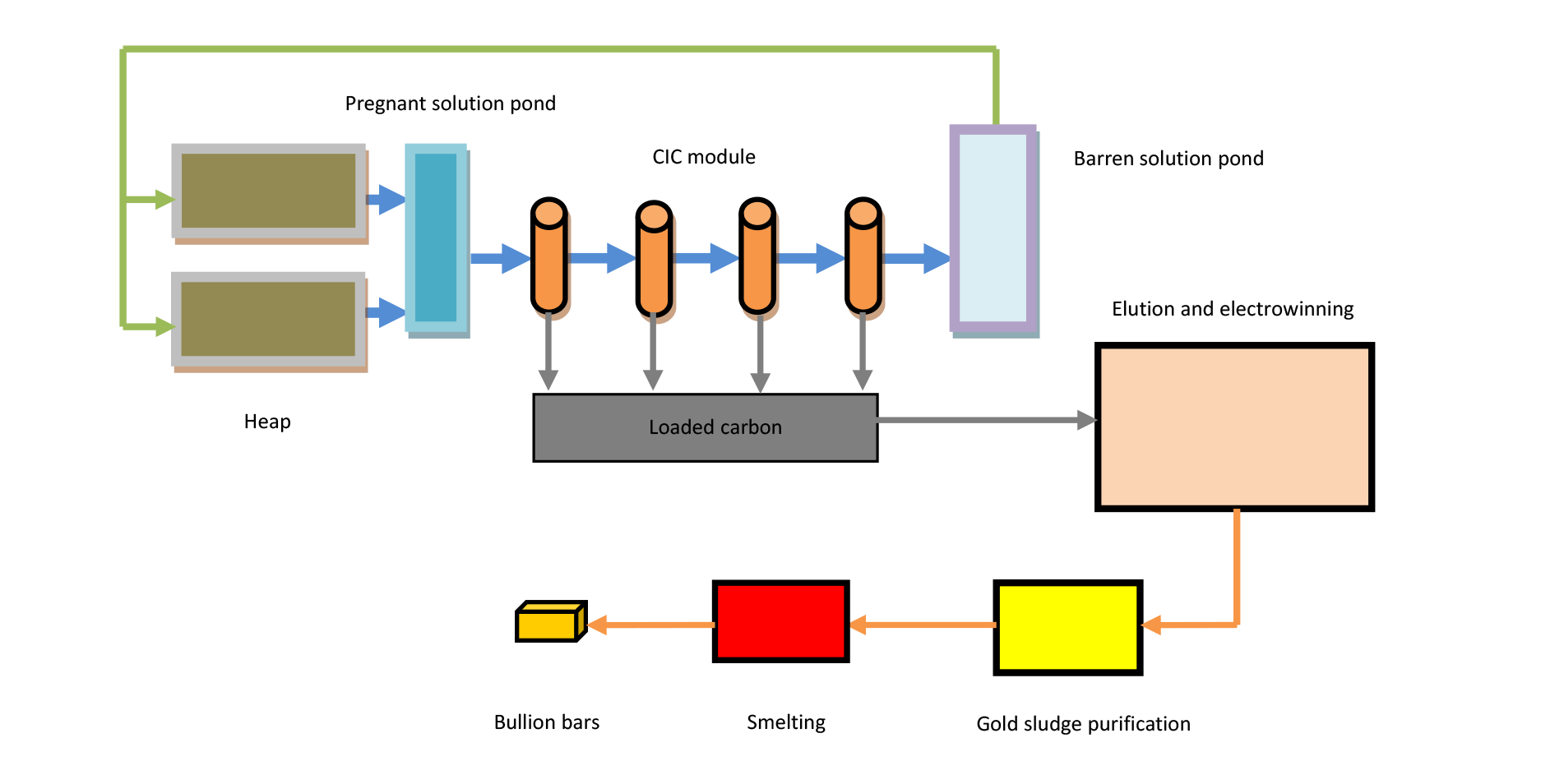

The pregnant solution (gold bearing solution) generated by leaching is collected into the pregnant solution pond. Then the solution is pumped into a modular CIC (carbon in column) unit consisting of a series of carbon adsorption columns.

After gold is adsorbed in the CIC unit, the pregnant solution becomes the barren solution which is pumped back to the heap for leaching.

The loaded carbon after full adsorption is burned or sent to the elution-electrowinning system to recover gold.

HZE design the heaps of hundreds to tens thousands of tons and their corresponding leaching and adsorption systems. Also HZE dispatch the engineers to guide on-site heap construction, materials loading, commissioning, trial production, unloading and the next processes and provide with the comprehensive and meticulous operation training and service guarantee.