Chrome Beneficiation and Processing Plant

HZE will conduct feasibility studies based on the condition of the raw ore, the metallurgical test report, the customer's mineral reserves and investment scale, and the conditions for building the plant, then propose a complete set of solutions for the plant which includes engineering design, equipment manufacturing and supply, Logistics, installation, commissioning, training, trial production and so on to ensure advanced technology, perfect processing, efficient plant construction, reduced investment, environmental protection and maximum benefits.

Chromium is the most widely used metal and its mineral beneficiation processing include:

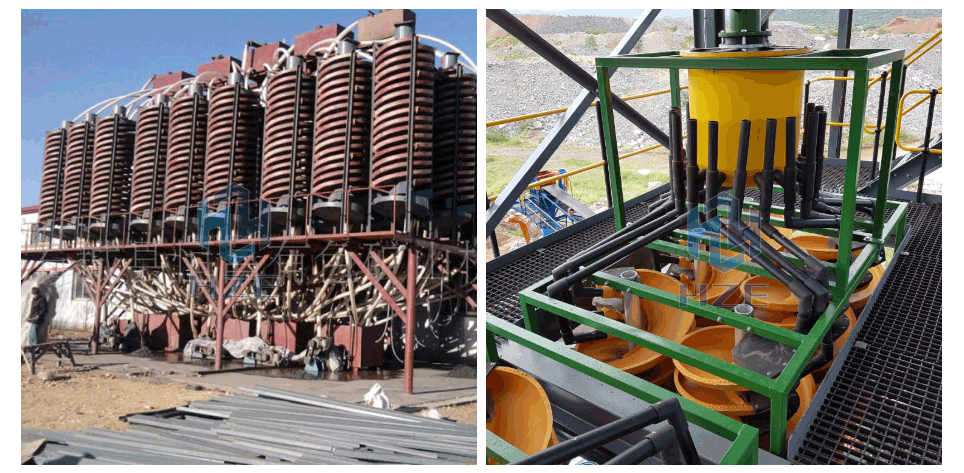

(1) Gravity concentration: jig, shaking table, spiral concentrator, heavy medium cyclone, etc.

(2) Magneto-electric separation: high-intensity magnetic separation and high-voltage electric separation.

(3) Flotation and flocculation flotation.

(4) Joint processing: such as gravity concentration and electric separation.

(5) Chemical processing: treat extremely fine and low grade chrome ores.

In the above-mentioned chromium ore processing, gravity concentration is mainly used in production and the shaking tables and jigs are often used to separate. Sometimes the concentrate obtained by gravity concentration are re-separated by low-intensity magnetic separators or high-intensity magnetic separators to further improve the grade of chrome concentrate and the ratio of chrome to iron.

The separated concentrate is generally dewatered then packed and sold.

The tailings are pumped to the tailings impoundment or the tailings are dewatered for dry stacking.